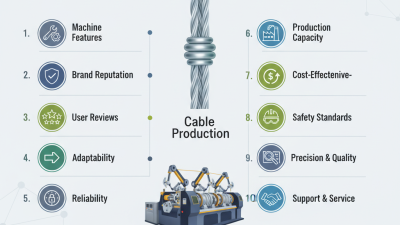

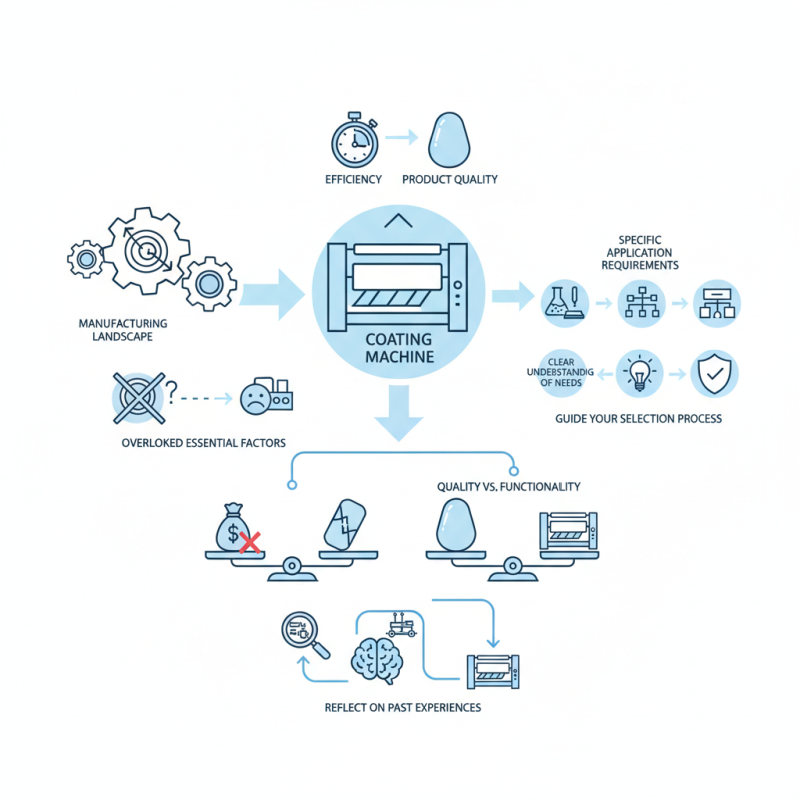

In the ever-evolving landscape of manufacturing, choosing the right Coating Machine is crucial. A well-selected machine can enhance efficiency and product quality. However, many overlook essential factors in their decision-making process. This can lead to regrettable choices that impact production lines negatively.

When evaluating coating machines, consider your specific application requirements. Different coatings serve varying purposes. Understanding these can save time and resources. Many users feel overwhelmed by the options but need focused criteria. A clear understanding of your needs will guide your selection process.

Investing in a Coating Machine isn't only about price. It's about balancing quality with functionality. Poor choices can lead to frequent breakdowns or subpar products. Reflecting on past experiences can help refine your approach to selecting the best machine for your needs.

When selecting a coating machine, understanding the different types available is crucial. The market offers several options, including spray, dip, and powder coating machines. Each type serves specific needs and industries. For instance, according to a recent industry report, spray coating machines account for approximately 45% of the market share. This is largely due to their versatility and efficiency in applications.

Tip: Assess your workspace before choosing a machine. Size and layout impact functionality and efficiency. Consider the materials you’ll be coating; they influence the choice of the coating type. Powder coating, for example, is often preferred for its durability. It can often reduce waste by recycling unused powder.

Another aspect to ponder is automation. Automated coating machines are gaining traction, reported to improve productivity by up to 30%. However, they can be a significant investment. Smaller operations may find manual machines more economical. Carefully weigh costs against your expected output.

Tip: Regular maintenance of coating machines can extend their lifespan. Keep an eye on components, and ensure they are in good working order. Small adjustments can make a big difference in performance. Reflect on your production goals and choose a machine that aligns with them.

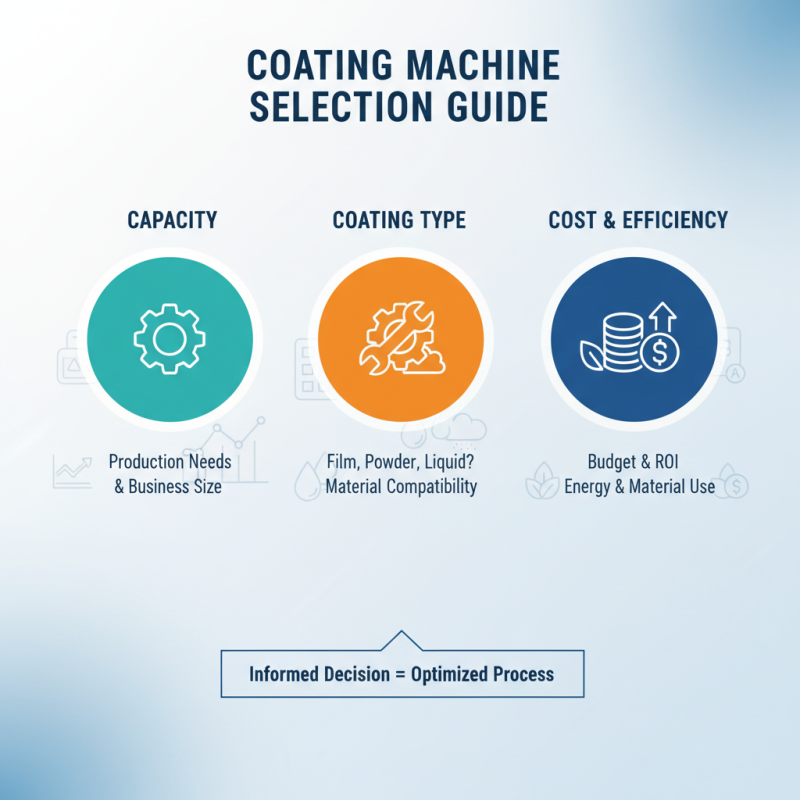

When selecting a coating machine, several key factors should guide your decision. Capacity is crucial. Understand your production needs first. A machine that can't keep up may slow down your entire process. Consider the size of your business and project demands.

Material compatibility is another important aspect. Make sure the machine can handle the types of materials you'll be using. Not every machine works well with all substances. Testing is invaluable here; run trials to see if it meets your specifications.

**Tips:** Look for machines that are adaptable to different materials. This can save you time and costs in the long run. Evaluate your space for the machine’s dimensions. A poor fit can disrupt workflow. It’s wise to seek feedback from operators on the machine's usability. Continuous improvements depend on real user experiences.

When assessing your production needs and requirements, start with clarity. Identify your production volume. Will you run small batches or large-scale operations? This decision impacts the type of coating machine you need. A compact machine might suffice for small runs, while larger operations require more robust equipment.

Consider the type of materials you will process. Different coatings and materials demand specific machines. For instance, a machine designed for liquids may not work well for powders. Understand your current and future needs. A machine that fits today’s requirements might not accommodate future changes.

Tips: Evaluate the machine's versatility. Can it handle multiple materials? Also, factor in maintenance needs. A machine that’s easy to clean and service saves time and money. Don’t hesitate to reach out to industry experts for insight. Their experience can help you avoid common pitfalls. Analyze your workflow too. A poorly integrated machine can slow down production. Balancing efficiency and capability is vital for success.

When selecting a coating machine, cost-effectiveness is key. It’s essential to assess not only the initial price but also long-term expenses. Maintenance costs, energy consumption, and material wastage can add up quickly. Many may overlook these factors, assuming the upfront payment is the only concern. A cheaper machine might save money initially, but higher operation costs can negate any savings.

Consider the type of coating finish needed for your products. Different machines serve various purposes. Some might struggle to achieve specific finishes, leading to rework and more expenditures. Research is vital before making a decision. Ask questions and seek expert insights to avoid making uninformed choices.

Efficacy is attractive, but evaluate how it aligns with your production needs. Sometimes, a slower machine may offer better quality. This highlights a common dilemma: speed versus quality. Balancing these aspects can be tricky. A thorough analysis of operational metrics can help. Don't forget to factor in the potential for future scalability. Investing wisely means considering how your needs might change over time.

When selecting a coating machine, maintenance and support are crucial for optimal performance. Regular maintenance extends the life of your machine. Simple tasks like cleaning and lubrication can prevent major breakdowns. Schedule routine checks to catch issues early. Keep a maintenance log to track efforts over time. This can help identify patterns and prevent future problems.

Support is equally important. Sometimes, machines fail despite our best efforts. Access to reliable technical support can make a difference. Read reviews and talk to other users to gauge support quality. Some manufacturers offer extended warranties, which can be beneficial. However, understand the limitations of such options.

Trained personnel are necessary for maintenance tasks. Ensure your team knows how to handle the equipment properly. Mistakes can lead to costly repairs and downtime. Investing in training pays off long-term. Communication with your team about the machine's performance is essential. Make it a habit to discuss any irregularities early.