The landscape of cable recycling is evolving rapidly. Innovations in Cable Recycling Equipment are transforming how we handle waste materials. These technologies not only improve efficiency but also promote sustainability.

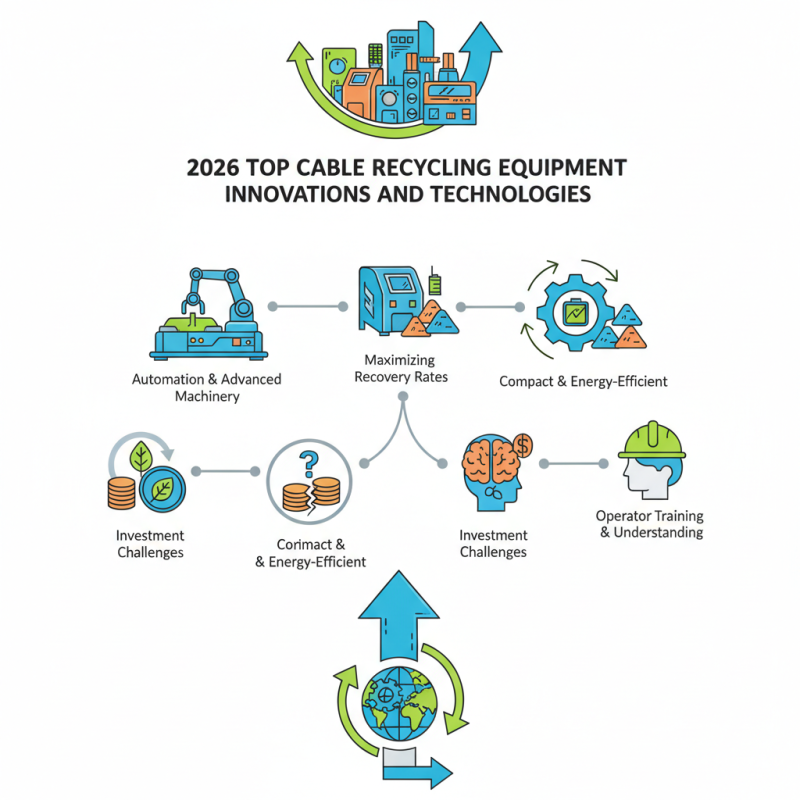

By 2026, we can expect advanced machinery that integrates automation. New designs will focus on maximizing recovery rates. Equipment will become more compact and energy-efficient. However, challenges remain in adoption and implementation.

Many businesses may struggle to invest in these innovations. There might not be enough training for operators. It’s crucial to ensure that everyone understands the new technologies. Overall, while optimistic about the future, it’s important to reflect on these potential shortcomings.

The world of cable recycling is evolving rapidly. Recent studies suggest that the cable recycling market is expected to reach $12 billion by 2026, driven by innovations in equipment technology. This growth reflects the increasing awareness of environmental issues and the need for sustainable practices in waste management.

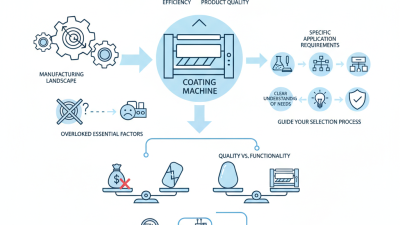

One notable innovation is the development of advanced granulation systems. These systems enhance material recovery rates significantly, achieving up to 99% separation efficiency. However, operational challenges remain. Many facilities struggle to optimize these systems due to insufficient training or maintenance, leading to lower performance than expected.

Another area of development is the use of artificial intelligence in sorting processes. AI can streamline the identification of different cable types, making recycling more efficient. Yet, this technology requires significant investment and expertise. Many companies find it difficult to integrate these systems into existing workflows. While innovations promise better solutions, the transition is not always seamless, highlighting a need for further exploration and improvement in operational strategies.

The cable recycling industry is witnessing rapid advancements, thanks to innovative technologies. New methods focus on efficiency and sustainability. For instance, automated cable stripping machines can now process cables faster than ever. This automation reduces human error and saves labor costs. Reports show that automation can increase processing efficiency by up to 30%.

Moreover, advanced pyrolysis technology is gaining traction. It breaks down cable insulation at high temperatures. This process yields valuable byproducts like oil and gas. Analysts predict that the use of pyrolysis in cable recycling could potentially cut waste by 50% over the next decade. However, the technology's high initial costs and energy consumption raise questions about its long-term viability.

Furthermore, data from the International Cable Recycling Association highlights the need for better sorting methods. Current manual sorting processes often lead to contamination. Innovations in optical sorting are emerging, offering improved precision. Yet, the effectiveness of these technologies varies widely. Some facilities struggle to implement them properly. This inconsistency points to a larger challenge in the industry.

The cable recycling industry is evolving. Eco-friendly materials now play a crucial role. Innovations focus on reducing waste and energy usage. Reports suggest over 30% of waste materials can be repurposed. Sustainable practices are essential for improving recycling rates.

New technologies enable the safe extraction of copper and other metals. They reduce environmental harm and cut costs. Not all equipment meets these standards, though. Some still release harmful substances. It’s vital to choose systems that are proven to be sustainable.

Tips: Choose equipment certified for eco-friendly processing. Regularly audit recycling practices for compliance. Monitor energy efficiency of machinery to reduce carbon footprint. Embracing these measures can lead to long-term benefits. Transitioning to sustainable methods requires reflection and commitment. The path to greener recycling is ongoing.

| Technology | Description | Innovation Type | Eco-Friendly Feature |

|---|---|---|---|

| Automated Wire Strippers | Machine that efficiently strips insulation from cables without damaging the wire. | Efficiency | Reduces waste and enhances recovery of reusable materials. |

| Granulator Machines | Equipment that cuts cables into small pieces for better material separation. | Material Processing | Increases efficiency in recycling processes, minimizing landfills. |

| Electrostatic Separators | Technology used to separate metals from plastics through electrostatic charges. | Separation | Highly effective in recovering valuable materials with low environmental impact. |

| Cable Shredders | Machines that shred cables into manageable pieces for further processing. | Pre-processing | Improves recycling rates and reduces energy required for subsequent processes. |

| Advanced Sorting Systems | Utilizes AI and machine learning for precise sorting of recyclable materials. | Automation | Enhances recycling efficiency and promotes circular economy practices. |

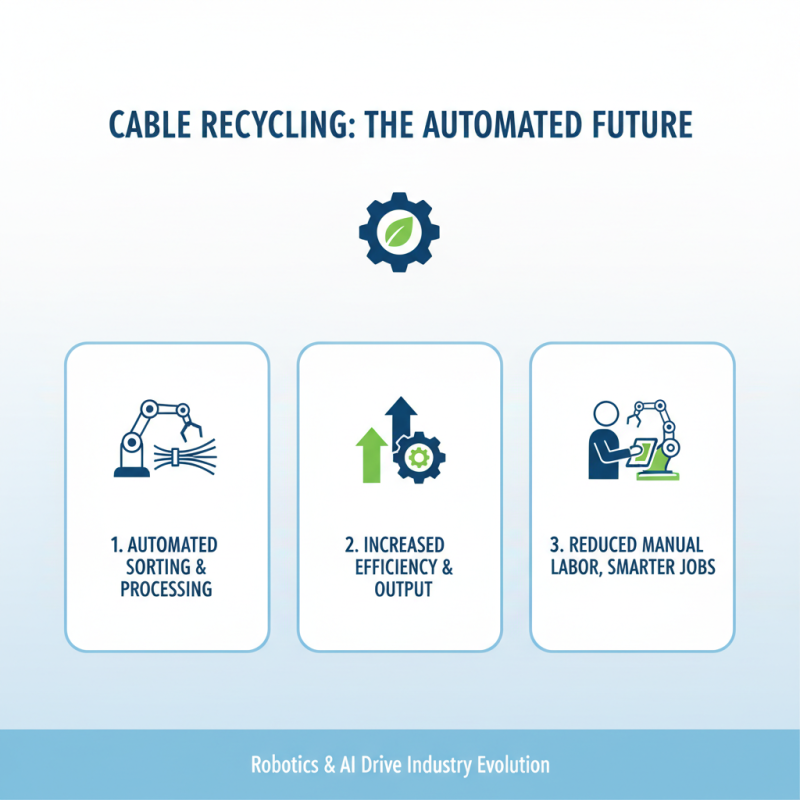

The cable recycling industry is undergoing a significant transformation, driven by automation and robotics. Advanced technology is streamlining the sorting and processing of cable materials. These innovations increase efficiency and reduce manual labor requirements. With robotic systems, operators can focus on higher-level tasks while machines handle repetitive jobs.

Current robotic solutions can identify different materials within cables. They use sensors and cameras to ensure accurate separation. This technology enhances recycling, but it's not without its challenges. Robotics can struggle with complex cable designs. Not all systems are equipped to manage intricate structures. There is a need for ongoing improvement in this area.

Automation also brings the potential for increased safety. Reducing human interaction with hazardous materials limits exposure to risks. However, implementing these systems requires proper training. Employees must adapt to new technologies, creating a potential knowledge gap. The journey toward optimal efficiency is still unfolding in the cable recycling sector.

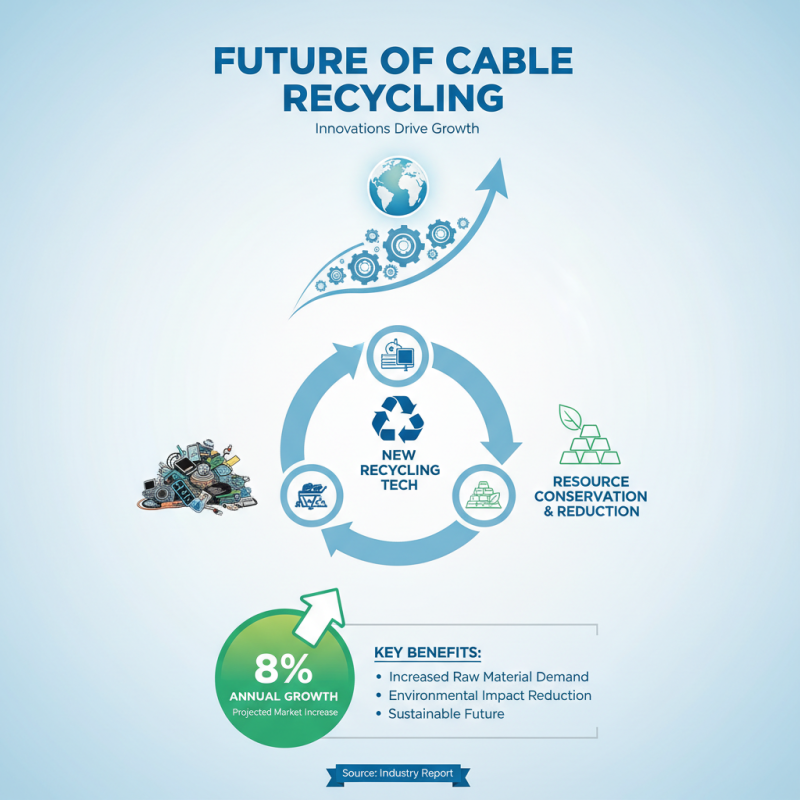

The future of cable recycling equipment is bright, driven by innovative technologies. According to a recent industry report, cable recycling is projected to grow by 8% annually. This shift is largely due to increased demand for raw materials. Recycling metals from cables not only conserves resources but also reduces environmental impact.

Current innovations focus on improving efficiency. More advanced shredders and separators now allow for better material recovery. These machines can handle different types of cables simultaneously, enhancing productivity. However, there's still room for improvement. Many facilities still face challenges in processing complex cable systems.

Tips: Consider investing in staff training. Well-informed employees can optimize equipment use. Additionally, keep an eye on regulatory changes. Compliance will shape future equipment standards. Lastly, think about upgrading machinery. Innovations are emerging quickly, and staying updated will lead to better results.