In the ever-evolving world of electrical components, the importance of Cable Testing Machines cannot be overstated. As technology advances, the demand for reliable performance grows. Industry expert John Smith states, "Investing in high-quality cable testing machines ensures safety and efficiency in every project." This highlights the crucial role these machines play in maintaining industry standards.

Cable Testing Machines are essential for verifying the integrity of cables. They help prevent failures that could lead to significant damage. However, choosing the right machine can be challenging. Many options exist, and not all meet the required standards. Some customers report dissatisfaction with products that did not perform as expected. This underlines the need for careful selection and research.

Understanding the features and specifications of top models is vital. Companies should focus on durability and accuracy in their equipment. While some machines boast many features, simplicity often leads to better results. There’s always room for improvement in the design and functionality of cables and their testing equipment. As we advance into 2026, the industry must prioritize innovations that enhance reliability and performance in Cable Testing Machines.

Cable testing machines play a vital role in ensuring reliability in various industries, such as construction, telecommunications, and automotive. These machines are essential for assessing cable performance under different conditions. In a report by MarketsandMarkets, the cable testing equipment market is projected to grow at a CAGR of 6.5% from 2021 to 2026, reflecting increasing industry demands for quality assurance.

Some key types of testing include tensile strength, electrical integrity, and insulation resistance. Each test provides insight into the cable’s durability and safety. For instance, improper tensile strength could lead to failures during installation. A study indicated that 30% of cable failures arise from inadequate testing practices. This statistic emphasizes the need for businesses to invest in reliable testing equipment to avert costly project delays.

When selecting a cable testing machine, reliability is paramount. One critical feature is the testing speed. According to industry reports, machines that test at high speeds can process up to 100 meters per minute. This speed can significantly enhance production efficiency. However, faster tests may lead to overlooked defects. Balancing speed and accuracy is essential, and often challenging.

Another important feature is adaptability. A versatile machine can test various cable types and configurations. This flexibility is crucial, especially in a market that demands customized solutions. Data suggests that 70% of manufacturers value adaptability due to evolving technology needs. Machines that lack this adaptability may require periodic upgrades, which can be costly.

Precision in measurement is also vital. Machines should ensure accurate readings to prevent future failures. Some testing units provide detailed real-time analysis. Yet, these sophisticated features can complicate operation. Operators need proper training to utilize all functionalities effectively. Investing in user-friendly interfaces may also be beneficial. Simplifying controls can enhance reliability and reduce errors during testing.

| Model | Measurement Range | Accuracy | Testing Speed | Key Features |

|---|---|---|---|---|

| Model A | 0-1000 V | ±1% | 100 m/s | Digital Display, Auto Calibration |

| Model B | 0-750 V | ±0.5% | 150 m/s | Bluetooth Connectivity, Compact Design |

| Model C | 0-500 V | ±2% | 80 m/s | User-Friendly Interface, Lightweight |

| Model D | 0-1200 V | ±0.8% | 200 m/s | Touch Screen Control, Advanced Diagnostics |

| Model E | 0-10000 V | ±0.3% | 300 m/s | High-Speed Testing, Versatile Connectivity |

In 2026, the cable testing equipment market is experiencing notable growth. Industry analysts forecast a compound annual growth rate (CAGR) of around 5.2% from 2023 to 2026. As technology progresses, manufacturers are focusing on enhancing reliability and performance. This has led to advancements in testing machines, catering to various sectors, including telecommunications and power distribution.

Market leaders in cable testing equipment are prioritizing precision. They implement advanced algorithms and automation techniques to improve testing efficiency. Reports indicate that more than 70% of users seek machines that can deliver accurate diagnostics quickly. However, there seems to be a gap. Many operators still find it challenging to interpret complex data from these machines. User interface design often falls short in providing clarity.

Additionally, training remains a crucial challenge. Despite high-quality machines, many technicians lack adequate training. An estimated 30% of users report difficulties in troubleshooting, which can hinder performance. Industry professionals emphasize the need for improved training programs. Manufacturers should prioritize user-friendly designs and training resources to enhance overall reliability. This could elevate operational efficiency and reduce errors in the field.

The reliability of cable testing machines relies heavily on adherence to stringent technical standards. Certification from recognized bodies ensures that machines meet industry safety and performance benchmarks. According to the International Electrotechnical Commission (IEC), equipment must comply with IEC 62067 for high-voltage testing. This standard ensures that machines can handle the demands of various cable types.

Many users often overlook the importance of regular calibration. Regular calibration ensures accuracy in testing. Reports indicate that up to 30% of machines may drift from specifications over time. Ignoring this can lead to unreliable results.

Tips for operators: Always check machine calibration before use. Familiarize yourself with ISO 17025 standards, as these can guide you in selecting properly accredited machines. Choose machines that are certified to relevant international standards, ensuring consistent performance in testing cables. It's essential to reflect on whether your testing practices align with the latest standards.

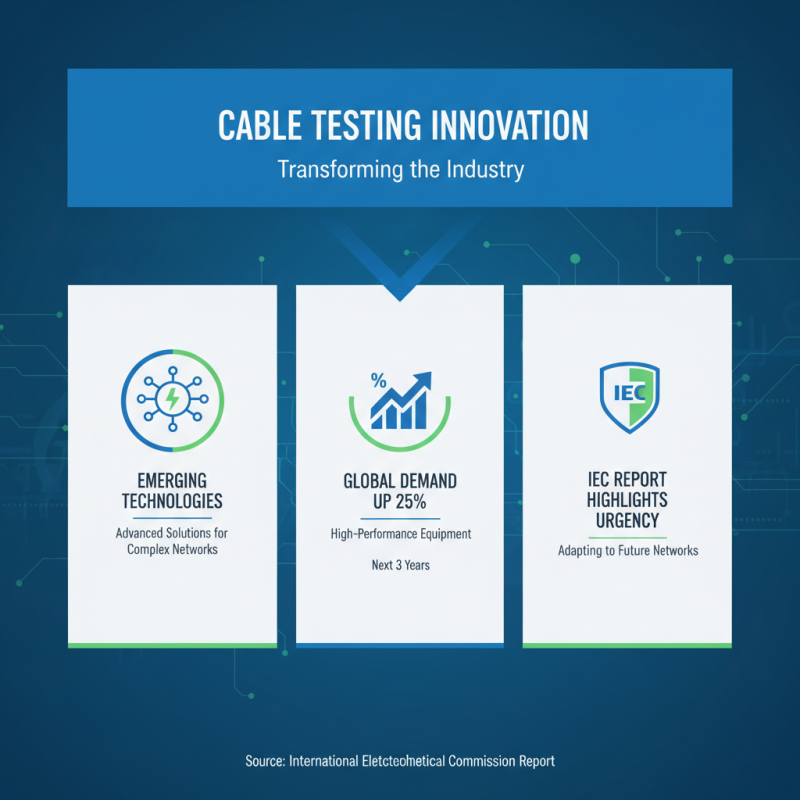

Emerging technologies in cable testing are transforming the industry. According to a recent report from the International Electrotechnical Commission, the global demand for high-performance cable testing equipment is expected to grow by 25% in the next three years. This growth highlights the urgency for advanced testing solutions that can adapt to complex networks.

New methods such as AI-driven analytics are enhancing test accuracy. These technologies help identify issues early, reducing costs significantly. A study by the Institute of Electrical and Electronics Engineers reveals that predictive maintenance can cut downtime by up to 40%. However, integrating such technologies is challenging. Many companies struggle with outdated systems that can’t leverage these emerging tools.

Additionally, the trend toward eco-friendly materials is reshaping testing requirements. Testing machines must now accommodate these advancements. But, many do not yet meet these standards. Continuous improvements are necessary to stay relevant. Companies must invest in research and development. Failure to adapt can lead to severe competitive disadvantages in this evolving landscape.