In the manufacturing world, Cable Drawing Machines play a vital role in producing high-quality wire products. According to a report by Research and Markets, the global market for cable drawing machines is expected to grow significantly, projecting a CAGR of 5.2% from 2021 to 2026. This growth is driven by increasing demand in industries like construction and automotive.

Selecting the right cable drawing machine can be a challenge. Different machines offer various features suited for specific applications. Issues like speed, efficiency, and energy consumption often arise in decision-making. Manufacturers continuously seek to improve productivity while reducing costs. Finding machines that strike this balance is crucial for staying competitive.

Certain machines excel in performance but may require higher initial investments. For instance, while some high-end models increase output, their complexity can be daunting for smaller manufacturers. Understanding these nuances can lead to better choices. The ideal cable drawing machine will ultimately depend on specific production needs and long-term goals.

Cable drawing machines play a crucial role in the manufacturing industry. These machines are designed to reduce the diameter of metal wires through a series of dies. The process involves pulling the wire through a die, which compresses and elongates it. This method not only strengthens the wire but also prepares it for further processing.

Understanding the mechanics behind cable drawing machines helps manufacturers enhance productivity. The setup might seem straightforward, yet there are complexities involved. Differences in die sizes and materials can affect the drawing process. Small errors might lead to defects in the wire. Observing the equipment during operation provides insight into these challenges. Regular maintenance is essential. Neglecting it can result in unexpected breakdowns. Every manufacturer can benefit from a deep understanding of their cable drawing equipment.

When choosing a cable drawing machine, several key features deserve attention. Speed is critical; faster machines increase productivity. However, too much speed can lead to defects. Balance is vital. Look for machines that allow adjustable speeds based on material types.

Another important aspect is the wire pulling force. This force impacts the quality of the final product. Insufficient pulling can result in uneven wires. Ensure the machine you choose offers the necessary force for your specific wire types. Paying attention to the materials used in construction is essential as well. Durable components reduce the need for frequent repairs.

Tips: Regular maintenance keeps machines running smoothly. Inspecting parts monthly can prevent bigger issues. Don't overlook training for operators; skilled hands can make a significant difference in production efficiency. It's crucial to test the machine before making a purchase. Conduct trials to understand its performance fully. This way, you avoid regrets later.

| Model | Maximum Draw Ratio | Wire Diameter Range (mm) | Speed (m/min) | Key Features |

|---|---|---|---|---|

| Model A | 1:16 | 0.5 - 5.0 | 20 | Automatic tension control, energy-efficient |

| Model B | 1:12 | 0.3 - 4.0 | 25 | Precision gear drive, adjustable speed settings |

| Model C | 1:14 | 0.8 - 6.0 | 30 | High torque, user-friendly interface |

| Model D | 1:10 | 1.0 - 7.5 | 22 | Noise reduction technology, customizable options |

| Model E | 1:18 | 0.6 - 5.5 | 18 | Fast setup, integrated monitoring system |

| Model F | 1:20 | 0.4 - 4.5 | 27 | Compact design, remote control functionality |

| Model G | 1:15 | 0.5 - 6.0 | 24 | Energy-efficient motors, safety features |

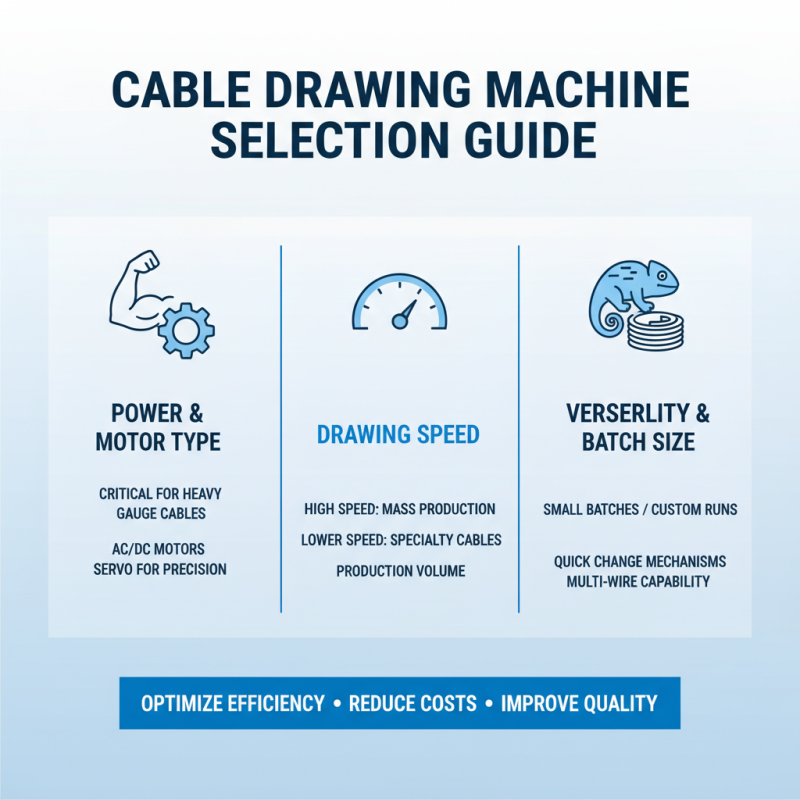

When it comes to cable manufacturing, selecting the right cable drawing machine is crucial. These machines vary significantly in terms of specifications and operational efficiency. Power, motor type, and drawing speed are essential factors to consider. Some machines operate at higher speeds, making them suitable for mass production. Others may offer more versatility, which can be beneficial for smaller batches.

Another vital specification is the machine's construction material. Machines made from robust, high-quality materials tend to last longer. However, they can also be more expensive. An expensive machine doesn't guarantee high efficiency or ease of use. Some users report issues with maintenance and operation, especially with complex models that require skilled technicians. It's a good idea to evaluate both performance metrics and user feedback to make a well-rounded decision.

Lastly, the cable drawing machine's design should facilitate ease of setup and use. Complicated interfaces can hinder productivity. Simple controls often lead to fewer mistakes and quicker learning periods for operators. Balancing innovation with straightforward functionality is essential, yet some machines overcomplicate their design. Finding an efficient machine might not just depend on specifications, but also on user experience.

When analyzing cable drawing machines, efficiency and performance stand out. Data suggests that optimized machines can enhance production speed by 30%. This improvement plays a crucial role in manufacturing competitiveness. A machine that draws wires consistently, even with varying materials, can save costs and reduce waste.

In a recent industry report, it was revealed that energy consumption is another vital metric. Machines that consume less power while maintaining high output can significantly affect operating costs. For example, some machines feature innovative cooling systems that can lower energy use by up to 15%. However, not all manufacturers leverage these advancements effectively.

Over time, manufacturers must reflect on their machinery choices. Many still rely on outdated models, impacting overall efficiency. Additionally, the need for regular maintenance is often overlooked. This neglect can lead to decreased performance, affecting production rates. Addressing these issues is essential for fostering a more productive manufacturing environment.

Regular maintenance of cable drawing machines is crucial for optimal performance. Industry reports indicate that proper upkeep can improve efficiency by up to 20%. Key tasks include lubricating moving parts and checking for wear and tear. Machine downtime can be costly. Therefore, a proactive maintenance schedule is essential.

Operators should conduct daily inspections. Look for loose connections or unusual noises. These could signal upcoming failures. A study revealed that 30% of equipment issues stem from neglect. Simple checks can prevent major breakdowns. Keeping the machine clean is equally vital. Dust and debris can clog mechanisms, reducing throughput.

Understanding the machine’s operational limits is critical. Running machines beyond their capacities can lead to overheating. This not only shortens the lifespan but also affects product quality. Regular training for operators can enhance awareness. Well-informed staff are less likely to push machines past their limits. Addressing these aspects leads to a more efficient manufacturing process.

This bar chart illustrates the production output (in kilometers) of seven different types of cable drawing machines over a one-month period. The data reflects the efficiency of each machine based on their specifications and operational conditions.