In the rapidly evolving world of Cable Machinery, innovation is key. Experts in the field highlight the importance of embracing new technologies to enhance efficiency. John Doe, a renowned industry leader, once stated, "Innovation in Cable Machinery will define the future of operations." This sentiment inspires many to rethink traditional methods.

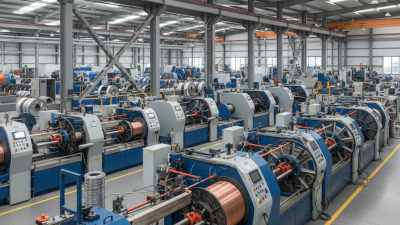

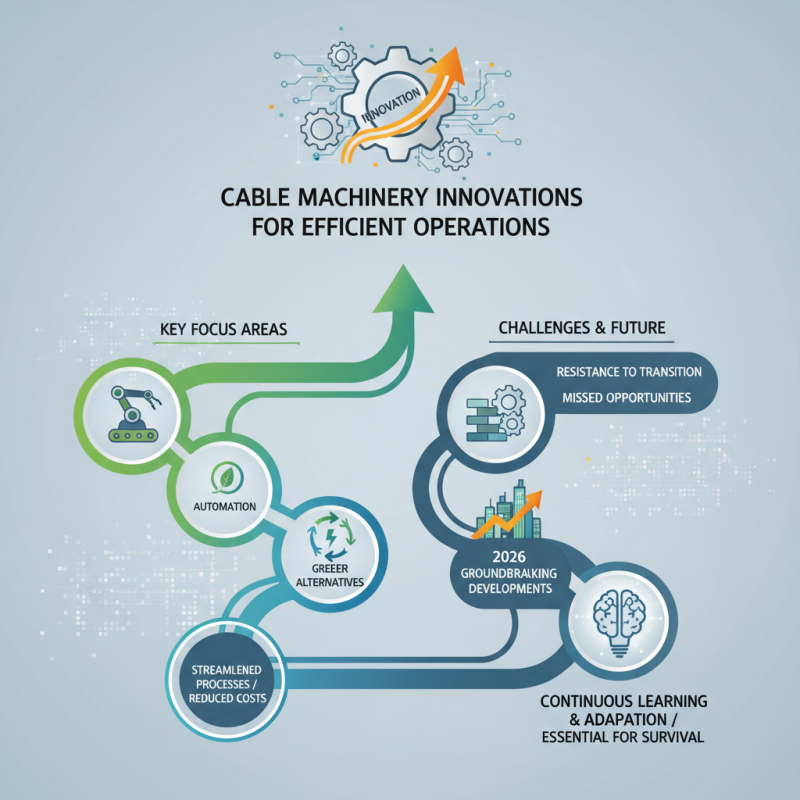

Recent innovations in Cable Machinery focus on automation and energy efficiency. These advancements aim to streamline processes and reduce costs. Industry players are pushing for greener alternatives that lower carbon footprints. However, not all companies adapt easily to these changes. Resistance to transition can hinder growth and lead to missed opportunities.

The year 2026 promises groundbreaking developments. As we explore the best innovations on the horizon, challenges remain. Some may struggle to keep pace with technological advancements. Continuous learning and adaptation will be vital for success in this dynamic environment. Embracing change in Cable Machinery is not just beneficial; it's essential for survival.

In 2026, cable machinery innovations have transformed various industries. These advancements focus on improving efficiency and optimizing performance. The latest technologies, including advanced robotics and automation, streamline processes. They reduce downtime and enhance productivity.

One key trend is the integration of AI in cable manufacturing. AI algorithms analyze data, predict failures, and suggest maintenance schedules. This proactive approach minimizes disruption. Another notable innovation is the development of energy-efficient cable machines. These machines consume less power, contributing to sustainability efforts.

Tips: Consider investing in training programs for your team. Understanding new technologies is crucial. Encourage open discussions about machinery usage. Feedback often reveals areas for improvement. Remember, even the best innovations can have flaws. Identifying these issues leads to better outcomes. Pay attention to real-world applications, and adapt accordingly.

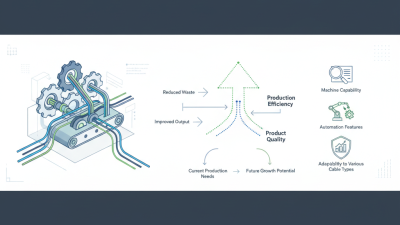

This chart showcases the innovative technologies introduced in the cable machinery sector in 2026. The data reflects the percentage of efficiency improvement attributed to each of these innovations.

The cable production industry is undergoing significant changes driven by innovative technologies. Key advancements focus on automation and artificial intelligence. These technologies enhance operational efficiency and consistency. According to a recent report, AI integration can reduce production costs by up to 25%. This creates exciting opportunities for manufacturers aiming to improve their bottom line.

Learning how to implement these technologies is crucial. Investing in smart machinery can facilitate predictive maintenance, thus minimizing downtimes. A study revealed that predictive maintenance can lead to an impressive 30% reduction in maintenance costs. However, many companies still lag in adopting these solutions, often due to budget constraints or lack of skilled workforce.

Tips: Start small. Test new technologies on a pilot scale before a full rollout. Training your existing staff is equally important. Invest in continuous learning programs to bridge the skill gap. Remember, it’s about gradual improvement, not perfection. Each small step can significantly enhance your cable production process over time.

| Innovation | Description | Key Benefits | Technologies Used |

|---|---|---|---|

| Smart Extrusion Systems | Advanced extrusion technology that optimizes material flow. | Increased production efficiency, reduced waste. | AI, IoT sensors |

| Automated Quality Control | Real-time monitoring of cable quality during production. | Enhanced quality assurance, lower defect rates. | Cameras, machine learning |

| Energy-Efficient Draw Machines | Machines designed for lower energy consumption during wire drawing. | Cost savings on energy, reduced carbon footprint. | Variable frequency drives, advanced lubrication systems |

| Integrated Data Management Systems | Centralized system for managing production data and analytics. | Improved decision-making and operational transparency. | Cloud computing, big data analytics |

| Robotic Handling Systems | Robots to handle materials and finished products automatically. | Increased safety, reduced labor costs. | Robotics, automation software |

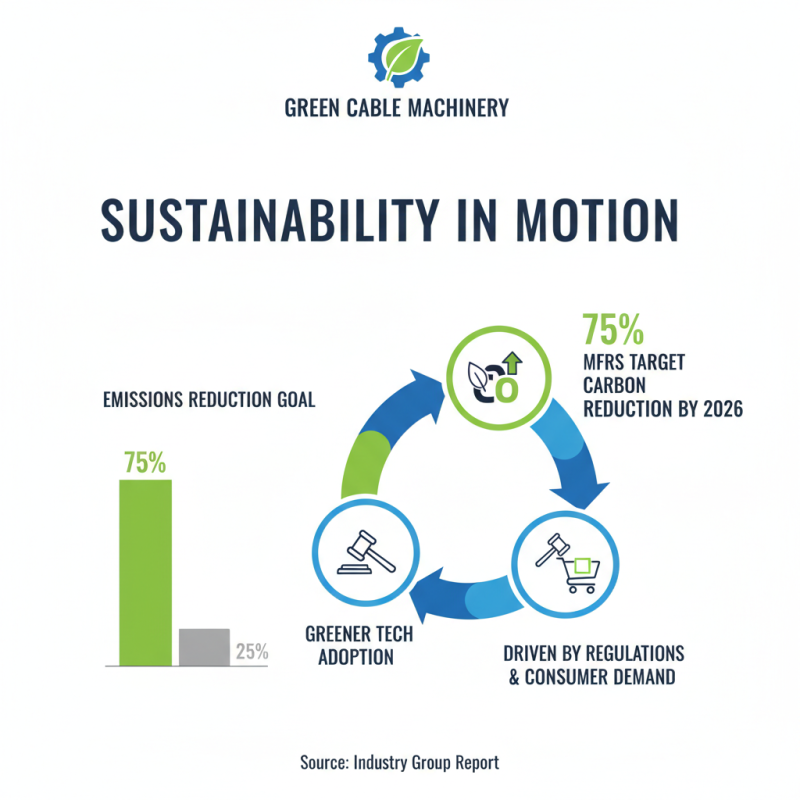

The cable machinery sector is increasingly focused on sustainability. Recent studies show that companies are adopting greener technologies. A report by an industry group indicates that 75% of manufacturers aim to reduce carbon footprints by 2026. This trend is driven by stricter regulations and consumer demand.

Innovative approaches such as using recycled materials are becoming common. For instance, some machinery now integrates components made from recycled plastics. This not only reduces waste but also lowers production costs. However, there are challenges. Many manufacturers struggle with sourcing high-quality recycled materials. This can limit the effectiveness of their sustainability efforts.

Energy-efficient machinery is also in the spotlight. Reports indicate that machines designed to optimize energy consumption can cut costs significantly. Yet, the initial investment can be daunting for smaller firms. Balancing cost and sustainability remains a complex issue. The transition to greener practices is essential, yet not all companies are ready. This uneven progress raises questions about industry-wide commitments to sustainability.

Evaluating cable machinery innovations involves using specific efficiency metrics. These metrics help organizations determine the true impact of new technologies. Common metrics include output rate, energy consumption, and overall equipment effectiveness (OEE). Monitoring these can highlight areas for improvement.

Tips: Regularly measure your energy usage. Set baseline metrics before implementing new machinery. This will help you track improvements accurately.

Sometimes, innovations fail to meet expectations. New machinery might promise faster operations but consume more energy. Assessing practicality is crucial. Understanding the real-world implications can prevent costly mistakes.

Tips: Conduct a pilot test before wide-scale implementation. Gather data on performance and energy costs. This can provide deeper insights into the actual benefits.

The cable industry is undergoing significant transformation due to automation and emerging technologies. Innovations in automation tools have streamlined production processes. Companies are investing in machinery that can handle tasks previously done by multiple workers. This progression leads to greater efficiency and reduced labor costs.

However, challenges remain. The transition to automated systems requires careful planning and training. Some employees may resist these changes, fearing job loss or skill redundancy. This can create a gap between management and workforce expectations. Open communication can help address these issues.

As technology advances, the potential for integration of artificial intelligence and IoT in cable manufacturing grows. These innovations promise to enhance monitoring and predictive maintenance. Yet, there is uncertainty about how effective these systems will be in real-life applications. Balancing innovation with the human factor is crucial for success in the evolving landscape of the cable industry.