In the ever-evolving landscape of the cable manufacturing industry, the importance of high-quality machinery cannot be overstated. Cable Armoring Machines play a critical role in ensuring durability and performance in cable production. However, the cost of new machinery can be prohibitive for many businesses. As a result, the market for Cable Armoring Machines Second-Hand is burgeoning, providing manufacturers access to reliable equipment at a fraction of the cost. According to a recent report from Market Research Future, the global demand for second-hand machinery is projected to grow by 15% over the next five years, underscoring the increased reliance on pre-owned equipment to maintain competitive advantages.

Industry expert Dr. Emily Chen, a leading authority on manufacturing efficiencies, notes, “Investing in Cable Armoring Machines Second-Hand not only reduces capital expenditure but also allows companies to enhance their production capabilities without compromising on quality.” This sentiment resonates with many businesses looking to balance financial constraints while upgrading their technology. Evaluating the top second-hand machines available on the market now can be a strategic move for manufacturers aiming to optimize operations and improve overall productivity. In the following sections, we will delve into the top 10 best second-hand Cable Armoring Machines that should be on every manufacturer’s radar, ensuring that they make informed, beneficial decisions.

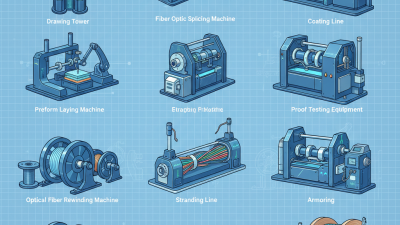

Cable armoring machines play a crucial role in the manufacturing process of cables, particularly for those designed to withstand harsh environments and physical stress. These machines are engineered to apply protective armoring around the cable, utilizing various materials such as steel or aluminum. The armoring serves a dual purpose: it not only enhances the mechanical strength of the cable, making it resilient against abrasion and impact, but also protects it from external elements such as moisture and chemicals. This protection is essential for cables used in industries like telecommunications, transportation, and energy, where reliability and durability are paramount.

In an increasingly competitive market, investing in high-quality second-hand cable armoring machines can be an economical choice for manufacturers looking to upgrade their production capabilities without incurring the high costs associated with new equipment. These machines can significantly improve production efficiency and maintain consistency in quality. The importance of selecting a reliable machine cannot be overstated, as the performance of the armoring process directly affects the lifespan and effectiveness of the finished cables. Thus, understanding the nuances and functionalities of these machines becomes essential for businesses aiming to enhance their operations and meet industry demands.

| Machine Model | Production Capacity (m/min) | Max Cable Diameter (mm) | Weight (kg) | Condition | Price ($) |

|---|---|---|---|---|---|

| Model A | 120 | 25 | 500 | Good | 4500 |

| Model B | 150 | 30 | 600 | Fair | 4000 |

| Model C | 100 | 20 | 550 | Excellent | 5000 |

| Model D | 130 | 28 | 470 | Good | 4200 |

| Model E | 110 | 22 | 560 | Fair | 3900 |

| Model F | 140 | 26 | 480 | Excellent | 4700 |

| Model G | 125 | 24 | 520 | Good | 4300 |

| Model H | 115 | 23 | 530 | Excellent | 4600 |

| Model I | 135 | 29 | 550 | Fair | 3800 |

| Model J | 145 | 32 | 590 | Good | 4100 |

When considering the purchase of second-hand cable armoring machines, it's crucial to establish specific criteria to ensure that you're making a wise investment. First, assess the machine's condition and operational history. Look for signs of wear and tear, such as rust or unusual noises during operation, which can indicate the need for costly repairs. Additionally, inquire about the machine's maintenance records, as a well-maintained machine is likely to perform better and have a longer lifespan.

Another important factor is compatibility with your existing production line. Ensure that the machine meets the specifications needed for your particular applications, such as the types of cables you plan to work with and the desired production capacity. Furthermore, evaluate the availability of spare parts and technical support for the machine model in question. Having reliable access to components and assistance will alleviate any downtime issues that may arise after the purchase. By focusing on these criteria, you can make an informed choice and select the best second-hand cable armoring machine for your needs.

When considering second-hand cable armoring machines, it's crucial to focus on the top brands that have built a reputation for quality and reliability in the industry. These brands often provide machines that have been rigorously tested for performance, ensuring that they meet the rigorous demands of cable production. Opting for well-established manufacturers means you are more likely to find machines with a robust support network, including access to spare parts and technical assistance, which is essential for maintenance and efficiency.

Another important aspect to consider is the technology used in these machines. Leading brands invest in research and development to incorporate the latest advancements in cable armoring technology. This can translate into increased production speed, better material handling, and enhanced overall efficiency. Buyers should pay close attention to the machine specifications and features offered by these brands to ensure they align with their production goals. By focusing on reputable brands, operators can significantly reduce the risk associated with purchasing second-hand machinery, ensuring that their investment remains sound over time.

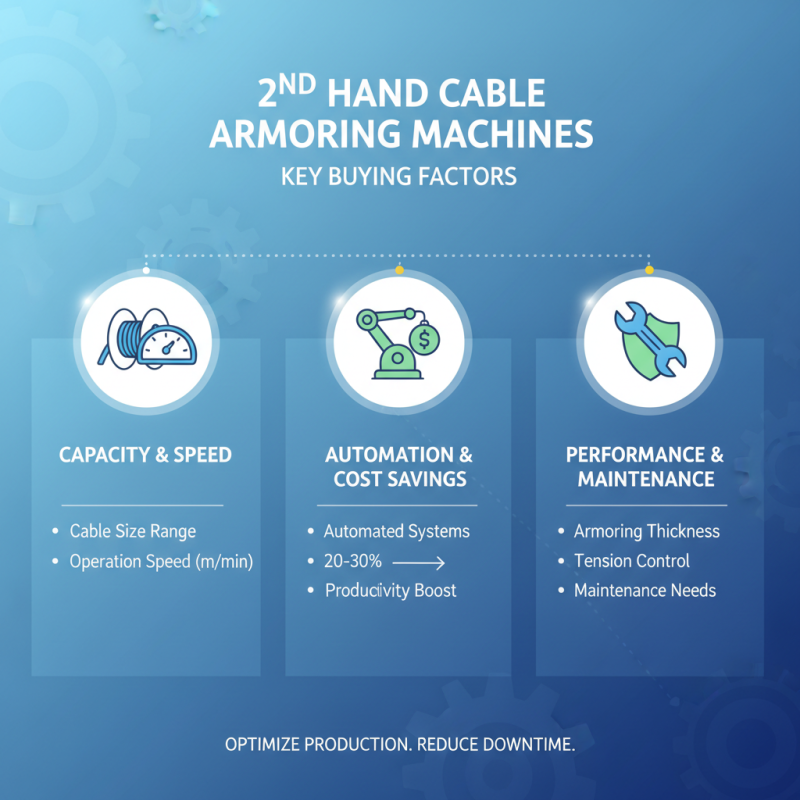

When considering the purchase of second-hand cable armoring machines, it's crucial to carefully analyze their features and specifications to ensure optimal performance and reliability. Typical features to evaluate include the machine’s capacity to handle different cable sizes, the speed of operation, and maintenance requirements. According to industry reports, machines with automated systems tend to reduce labor costs and downtime, enhancing overall productivity by an estimated 20-30%. Inspecting operational parameters, such as the maximum armoring thickness and tension control, can help in determining the suitability of each machine for specific projects.

A significant consideration is the machine’s age and previous usage history. A machine that has undergone regular maintenance and replacement of key components often proves more reliable than newer models that may lack thorough servicing. Additionally, it’s advisable to review the availability of spare parts, as machines with a robust support network tend to reduce operational hiccups significantly. Research indicates that around 15% of downtime in manufacturing processes stems from equipment failure, emphasizing the importance of investing in a well-maintained machine.

Tip: Always request a detailed inspection report and maintenance log before finalizing a second-hand purchase. This documentation can provide invaluable insight into the machine's operational history and potential longevity. Another helpful tip is to explore user reviews and feedback from previous owners, as these can highlight both the strengths and weaknesses of specific models in real-world applications, ensuring an informed purchase decision.

Proper maintenance of second-hand cable armoring machines is crucial for ensuring optimal performance and extending the lifespan of the equipment. According to industry standards, the average lifespan of cable armoring machines can range from 10 to 15 years, depending on usage and maintenance practices. Regular service intervals, typically every 500 operating hours, should include inspections of critical components like rollers, bearings, and drive systems to prevent unexpected breakdowns and costly repairs.

Additionally, routine lubrication of moving parts is essential, as it reduces friction and wear, significantly enhancing operational efficiency. A report by the International Electrotechnical Commission indicates that well-maintained machinery can improve productivity by as much as 20%. Furthermore, always keeping the machine clean and free from debris will prevent contamination that could lead to mechanical failure. Implementing a preventative maintenance plan not only mitigates the risk of costly downtime but also ensures compliance with safety and operational protocols within the cable manufacturing industry.