In today's rapidly advancing technological landscape, the "Cable Machinery" industry is undergoing a significant transformation fueled by innovative developments. According to Dr. Michael Reynolds, a leading expert in cable technology, "Innovation in cable machinery is not just a trend; it's a necessity for meeting the increasing demands of modern infrastructure." This statement encapsulates the urgency with which manufacturers must adopt new technologies to maintain competitiveness and efficiency.

From automated production lines to smart monitoring systems, these advancements are reshaping the capabilities and functionality of cable machinery. As we delve into the top ten innovations currently making waves in the industry, we will explore how these technologies are not only enhancing production processes but also improving flexibility and sustainability. By understanding these cutting-edge developments, stakeholders can position themselves strategically in an ever-evolving market that prioritizes both performance and eco-friendliness.

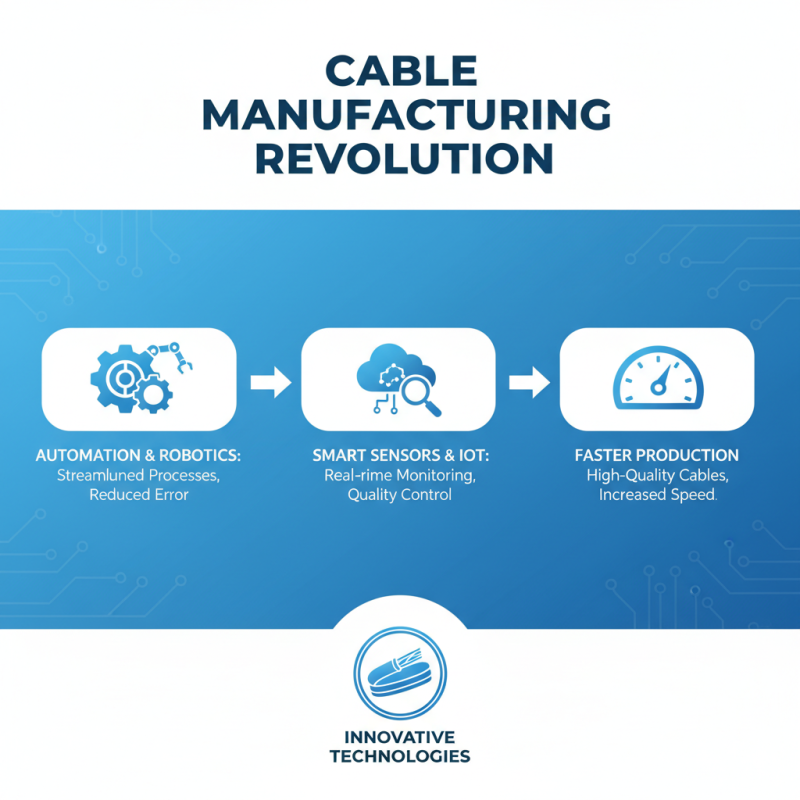

The production of cable machinery is undergoing a remarkable transformation, thanks to innovative technologies that are revolutionizing how cables are manufactured. The adoption of automation and advanced robotics streamlines processes, enhancing efficiency and minimizing human error. With the integration of smart sensors and IoT, manufacturers can monitor operations in real-time, leading to improved quality control and predictive maintenance. These innovations have made it possible to produce high-quality cables at a faster rate than ever before.

Tips: Embrace automation wherever feasible to reduce production times and errors. Implementing predictive maintenance through real-time monitoring can significantly extend the lifespan of machinery and reduce downtime.

In addition to automation, advancements in materials science are enabling the creation of lighter, stronger cables, which are essential for today's high-demand environments. Techniques such as 3D printing and additive manufacturing allow for rapid prototyping and customized cable designs. This shift not only boosts flexibility in production but also supports sustainable manufacturing practices by minimizing waste.

Tips: Explore the benefits of 3D printing in your production lines to enhance customization capabilities. Regularly review your materials to ensure you are using the latest innovations to meet industry standards and consumer demands.

The cable manufacturing industry is experiencing significant advancements in automation, fundamentally transforming the way cables are produced. Modern technologies, such as robotics and artificial intelligence, have enabled manufacturers to optimize production lines, minimize downtime, and enhance overall efficiency. According to a recent industry report by MarketsandMarkets, the global market for automated cable manufacturing machinery is expected to reach $1.5 billion by 2025, growing at a CAGR of 8.2% from 2020. This growth illustrates the increasing necessity for automation in meeting high product demand while maintaining precision.

One notable innovation is the use of smart sensors and IoT (Internet of Things) devices that monitor equipment performance in real-time. These technologies not only help in predicting maintenance needs but also streamline workflows by providing valuable data that aids in decision-making. A study by McKinsey highlights that companies that adopt IoT solutions can achieve a 15% increase in productivity while significantly reducing material waste.

Tips for manufacturers looking to enhance automation include investing in training for staff to effectively operate new technologies, and regularly assessing production processes for potential improvements. Integrating predictive analytics into manufacturing can further drive efficiency by forecasting demand and adjusting production schedules accordingly. Embracing these innovative tools will be crucial for staying competitive in the rapidly evolving cable industry.

As the cable machinery industry evolves, a significant shift towards eco-friendly solutions is becoming evident. Sustainable practices are now at the forefront of design and manufacturing processes, reflecting a growing commitment to environmental responsibility. Manufacturers are increasingly adopting materials that are recyclable or sourced from renewable resources, ensuring that the lifecycle of their equipment minimizes waste and energy consumption. This transition not only helps in reducing the carbon footprint but also appeals to an environmentally conscious market.

Moreover, innovative technologies are being developed to enhance the efficiency of cable machinery. For instance, energy-efficient motors and advanced control systems are being integrated into machinery designs to optimize power usage. These innovations lead to reductions in energy consumption during operation, aligning with sustainability goals. Additionally, companies are exploring the use of biodegradable lubricants and cutting fluids, which significantly reduce the ecological impact of manufacturing processes. By prioritizing sustainability in design, the cable machinery sector is not only transforming operational practices but also paving the way for a greener future in manufacturing.

The integration of IoT technologies in cable machinery is revolutionizing how the industry operates. Smart connectivity is enhancing productivity and efficiency across the production line, enabling manufacturers to monitor equipment in real-time. According to a recent industry report, approximately 45% of cable manufacturers are now utilizing IoT-enabled machinery, leading to a reduction in downtime by up to 30%. This innovative approach allows for predictive maintenance, which not only minimizes unexpected failures but also optimizes maintenance schedules, ultimately saving costs.

Implementing IoT technologies also facilitates data-driven decision-making. By collecting and analyzing data from connected machinery, businesses can identify patterns and trends that inform production strategies. This can lead to a more agile response to market demands and reduce waste by fine-tuning production processes. A study by a leading industry analyst predicts that IoT advancements could increase operational efficiency by 20% in the next three years as more manufacturers adopt smart technologies.

Tips: To capitalize on IoT benefits, manufacturers should invest in training their workforce on new technologies. Additionally, they should ensure robust cybersecurity measures are in place to protect sensitive data. Finally, collaborating with tech partners who specialize in IoT solutions can help tailor systems specifically for the unique needs of cable production.

| Innovation | Description | Impact on Industry | IoT Role |

|---|---|---|---|

| Automated Cable Cutters | Machines that automatically cut cables to specified lengths with precision. | Increases efficiency and reduces labor costs. | Remote monitoring of machine performance through IoT sensors. |

| Smart Spooling Systems | Systems that adjust spool tension based on real-time data. | Minimizes cable damage and improves quality. | Uses IoT to gather data on spool conditions continuously. |

| Predictive Maintenance | Technology that predicts equipment failures before they occur. | Reduces downtime and maintenance costs. | IoT sensors track wear and tear to inform maintenance schedules. |

| Cable Quality Monitoring | Systems that continuously assess the quality of the cables being produced. | Ensures high safety and performance standards. | IoT devices provide real-time quality data analysis. |

| Energy-Efficient Machinery | Equipment designed to consume less energy while maintaining performance. | Offers substantial cost savings and environmental benefits. | IoT allows for real-time energy consumption monitoring. |

| Robotic Cable Handling | Robots that handle cables during production and packaging. | Improves safety and reduces manual handling errors. | Supports IoT connectivity for task tracking and optimization. |

| Virtual Reality Training | Training simulations for operators using virtual reality technology. | Enhances skill development and safety awareness. | IoT integration allows for tracking progress and results. |

| Augmented Reality Maintenance Guides | AR tools that assist technicians during maintenance tasks. | Increases accuracy and decreases repair times. | IoT devices can push real-time updates to AR interfaces. |

| Cloud-Based Data Management | Systems that store and manage data remotely on cloud platforms. | Facilitates easier access to information and analytics. | IoT devices collect data that can be accessed from anywhere. |

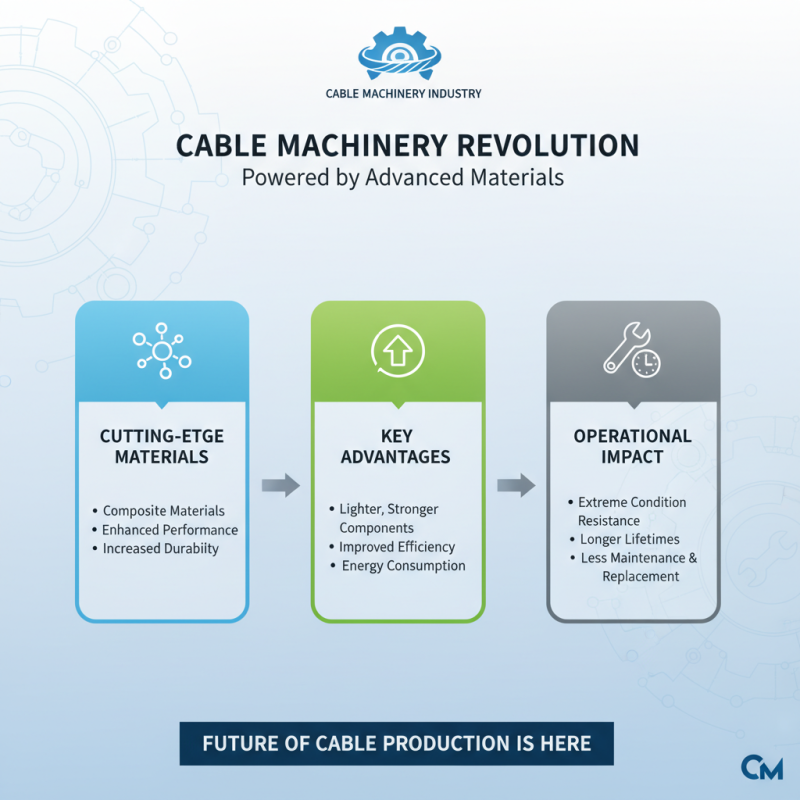

The cable machinery industry is experiencing a significant transformation, largely due to the integration of cutting-edge materials that enhance both performance and durability. Modern advancements in composite materials, for instance, have led to lighter and stronger machinery components, which ultimately improve efficiency and reduce energy consumption. These materials can withstand extreme environmental conditions without succumbing to wear and tear, ensuring longer operational lifetimes for cable machinery and reducing the frequency of maintenance and replacement.

Additionally, the use of innovative coatings and treatments has revolutionized the durability of cable machinery. These advancements help protect components from corrosion, abrasion, and thermal degradation, enhancing their resilience under varying operational stresses. This not only extends the lifespan of the equipment but also ensures consistent performance over time. As the industry continues to embrace these cutting-edge materials, manufacturers are better equipped to meet the evolving demands of cable production, paving the way for more sustainable and efficient processes.