In industries reliant on cable production and handling, the efficiency and longevity of operations heavily depend on the quality and availability of Cable Machinery Spare Parts. These components are essential for maintaining the seamless functioning of machinery used in various stages of cable manufacturing, from wire drawing to insulation and beyond. Understanding the intricacies of these spare parts is crucial for industry professionals tasked with optimizing performance, reducing downtime, and ensuring safety in operational environments.

Cable Machinery Spare Parts encompass a wide range of elements, including components that may wear out over time and require timely replacement. Professionals must be knowledgeable about the types of spare parts available, their specific applications, and the signs that indicate a need for replacement. This knowledge not only aids in sustaining operational efficiency but also extends the lifespan of costly machinery investments.

Furthermore, the selection of high-quality Cable Machinery Spare Parts can significantly influence the overall productivity and reliability of cable manufacturing processes. As technology evolves and production demands increase, staying informed on the latest developments in spare parts and their applications becomes imperative for industry professionals aiming to thrive in a competitive landscape. This guide aims to provide valuable insights into the world of Cable Machinery Spare Parts, equipping professionals with the knowledge needed to make informed decisions for their operations.

Cable machinery spare parts are critical components that ensure the efficient operation and longevity of cable manufacturing and processing equipment. These parts can range from simple nuts and bolts to complex assemblies, each designed to uphold the performance standards of machinery used in cable production. Understanding these components is vital for industry professionals, as the right spare parts not only minimize downtime but also enhance the overall productivity of manufacturing processes.

A comprehensive overview of cable machinery spare parts reveals their diverse categories, including drive systems, guides, payoffs, and tensioners. Each category serves a specific function within the machinery, with parts engineered to withstand the unique stresses associated with cable production. Regular maintenance and timely replacement of these parts can prevent costly interruptions and extend the lifespan of the machinery, making knowledge of these essential items indispensable for any professional in the cable sector. Moreover, familiarity with the specifications and compatibility of spare parts ensures seamless integration into existing systems, ultimately leading to improved operational efficiency.

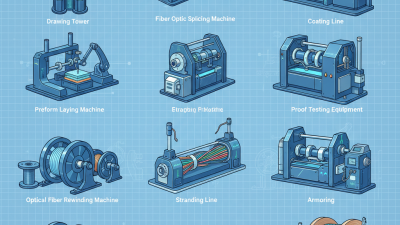

Cable machinery is composed of various components, each playing a crucial role in the overall functionality and efficiency of the equipment. Understanding the types of cable machinery spare parts is essential for industry professionals who aim to maintain optimal performance in their operations. Common spare parts include drive belts, which are responsible for transferring power from the motor to other components, ensuring smooth movement and operation of machinery. Additionally, bearings are vital for supporting rotating parts, reducing friction, and enhancing the longevity of the machinery.

Another significant category of spare parts includes electrical components like motors and controllers, which dictate the speed and torque of the machinery. These parts are critical for maintaining precise control over the production processes. Furthermore, cutting tools and dies are essential for shaping and manipulating cables, and their maintenance or replacement can directly impact the quality of the final product. Each of these components must be regularly inspected and replaced as necessary to ensure that cable machinery remains reliable and efficient in meeting production demands.

| Spare Part Type | Function | Common Applications | Materials Used |

|---|---|---|---|

| Cable Drum | Holds and manages the storage of various types of cables. | Electrical cable production, network installations. | Steel, plastic. |

| Cable Guide | Directs cable during the winding process to ensure proper lay. | Wire coiling machines, extrusion machinery. | Aluminum, brass. |

| Stranding Tool | Combines multiple wires or strands for enhanced durability. | Cable production, telecommunications. | Carbon steel, hardened steel. |

| Tension Control Device | Maintains consistent tension on the cable during processing. | Cable laying, winding operations. | Alloy steel, plastic composites. |

| Pulling Eyes | Facilitates easy pulling and installation of cables. | Telecommunications, industrial wiring. | Steel, high-strength fabric. |

When selecting spare parts for cable machinery, the importance of quality and standards cannot be overstated. High-quality spare parts are critical for ensuring the reliable operation of machinery, minimizing the risk of breakdowns, and prolonging the lifespan of equipment. Industry professionals must prioritize materials that meet rigorous standards and certifications. This approach not only guarantees that the parts will perform efficiently but also aligns with the best practices in safety and maintenance protocols.

Adhering to established standards in spare parts selection also fosters trust and accountability between suppliers and users. Quality assurance processes, such as inspecting and testing components, are essential practices that help prevent substandard parts from entering the supply chain. When industry professionals choose spare parts that comply with recognized standards, they benefit from increased operational efficiency and reduced downtime. Moreover, such practices contribute to a safer working environment, as reliable machinery is less prone to malfunctions that could pose hazards to personnel and operations.

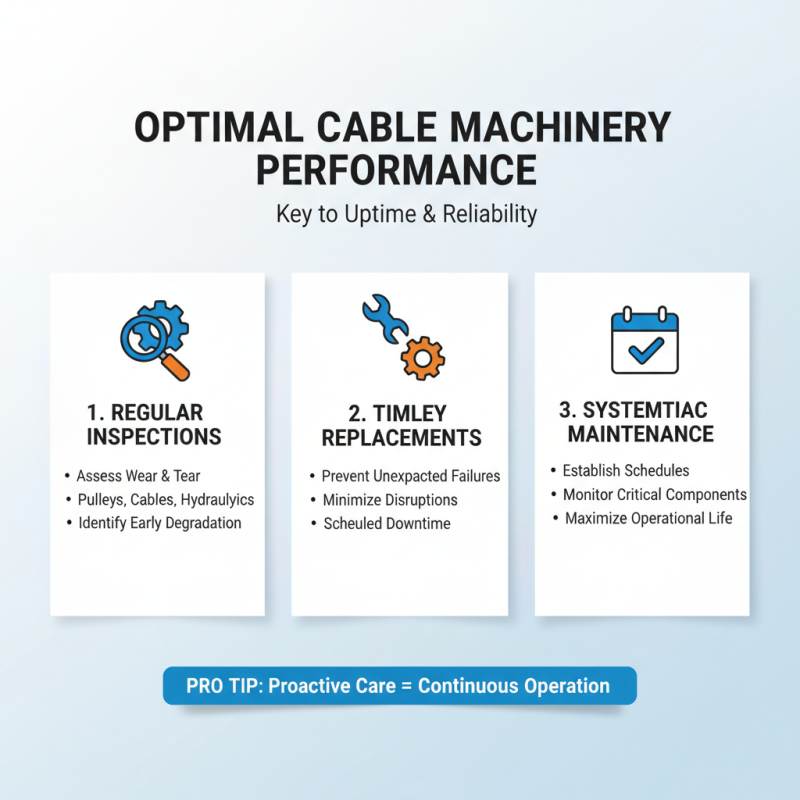

Maintaining optimal performance in cable machinery depends significantly on the condition of spare parts. Regular inspections and timely replacements are essential strategies for preventing unexpected failures that could halt operations. Industry professionals should establish a systematic maintenance schedule that includes assessing the wear and tear of critical components such as pulleys, cables, and hydraulic systems. By monitoring these parts, professionals can identify early signs of degradation and plan replacements during scheduled downtimes, thereby minimizing disruptions.

In addition to routine maintenance, implementing a comprehensive inventory management system for spare parts is crucial. This strategy not only ensures that essential components are readily available when needed but also allows for better forecasting of replacement needs based on usage patterns. Keeping track of part lifecycles and integrating it with operational data can help professionals anticipate failures before they occur. Furthermore, investing in training for staff on proper maintenance procedures and the importance of spare parts can enhance the longevity of machinery and improve overall efficiency in the industry.

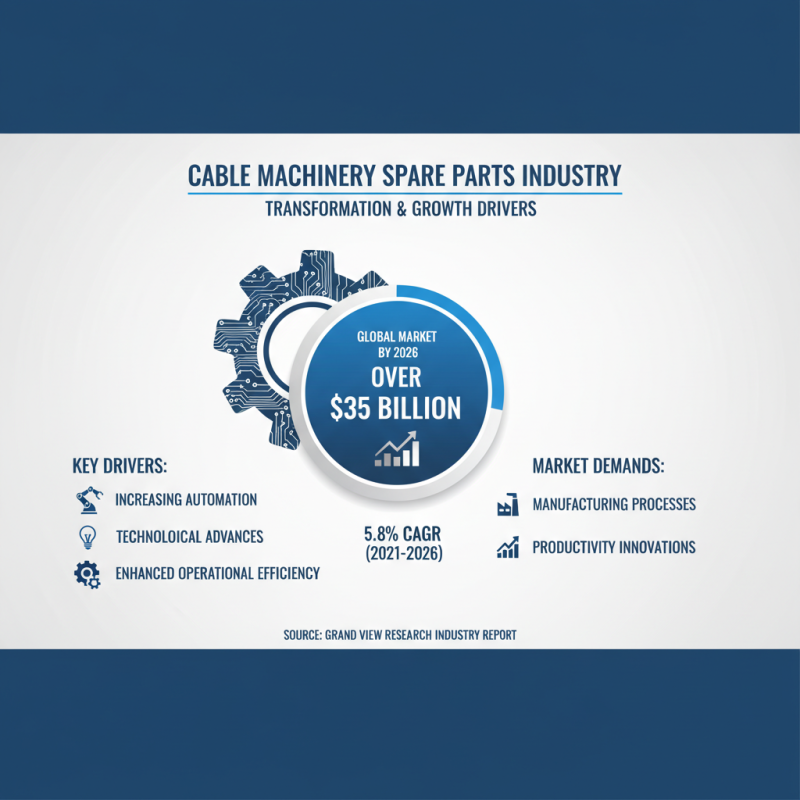

The cable machinery spare parts industry is undergoing significant transformations driven by technological advances and changing market demands. According to a recent industry report by Grand View Research, the global cable machinery market is projected to reach over $35 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.8% from 2021. This growth is largely fueled by the increasing automation in manufacturing processes and innovations in spare parts that enhance operational efficiency and productivity.

One of the key trends in this sector is the adoption of smart technologies such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies enable real-time monitoring and predictive maintenance of machinery, which minimizes downtime and reduces maintenance costs. A study conducted by MarketsandMarkets indicates that predictive maintenance solutions can lower maintenance costs by 20-25% and reduce downtime by 50%, showcasing the importance of innovative spare parts in modern cable machinery operations. Furthermore, the demand for eco-friendly materials in spare parts manufacturing is on the rise, aligning with global sustainability trends and regulations aimed at reducing environmental impact.

As industry professionals seek to stay competitive, investing in high-quality and innovative spare parts becomes essential. The ability to integrate advanced technologies into cable machinery not only enhances the lifespan of equipment but also significantly improves operational resilience. Keeping abreast of these trends and innovations will be crucial for professionals looking to optimize their machinery and meet the evolving demands of the market.