Cable Manufacturing Machines play a crucial role in the production of electrical cables, which are essential for various industries, including telecommunications, construction, and energy. According to a recent report from ResearchAndMarkets, the global market for cable manufacturing machinery is expected to grow significantly, with a forecasted CAGR of 4.8% from 2021 to 2026. This growth is driven by increasing demand for high-quality cables that support the expansion of infrastructure projects and the rising adoption of electric vehicles that require robust wiring systems.

Efficiency in cable manufacturing is critical, as it directly impacts production costs and output quality. Advanced Cable Manufacturing Machines incorporate innovative technologies like automation and real-time monitoring systems, which allow manufacturers to optimize their processes and reduce waste. A study by MarketsandMarkets highlights that automation in manufacturing can lead to efficiency improvements of up to 30%. As the industry evolves, understanding how these machines work and their operational efficiency becomes vital for manufacturers aiming to maintain a competitive edge in a rapidly changing market landscape.

Cable manufacturing machines are essential in the production of various types of cables used in numerous industries, including telecommunications, power distribution, and construction. These machines facilitate the efficient and precise fabrication of cables by automating processes such as wire drawing, stranding, insulation, and sheathing. Their ability to streamline production has led to increased output and improved quality, thereby meeting the growing demands of modern infrastructure and technology.

The importance of cable manufacturing machines cannot be overstated, as they contribute significantly to the overall efficiency of cable production. By minimizing human error and maximizing production speed, these machines enable manufacturers to produce cables with consistent specifications and qualities.

Moreover, advancements in technology, such as the incorporation of automation and data analytics, allow for better monitoring and control of manufacturing processes. This not only enhances productivity but also ensures that the cables produced meet stringent safety and performance standards, ultimately supporting the reliability of electrical systems and communication networks.

Cable manufacturing machines play a crucial role in the production of various types of cables, from low-voltage wiring to high-performance telecommunications lines. There are several key types of equipment involved in these processes, each designed for specific functions. For instance, extrusion machines are essential for forming the outer layers of cables, using heat to melt and mold materials into desired shapes. Additionally, stranding machines are vital for combining multiple wires into a single cable, ensuring both strength and flexibility.

Another important category of equipment includes cabling machines, which collate and assemble cables into broader configurations. These machines often incorporate automatic control systems that enhance precision and efficiency during the manufacturing process. Understanding the various types of machines and their functions is essential for optimizing production lines and improving overall output quality.

Tips: Regular maintenance of cable manufacturing machines is crucial for ensuring their long-term efficiency. Implementing a scheduled service routine can prevent unexpected breakdowns and improve machine longevity. Moreover, training staff on the operation of different equipment not only boosts productivity but also enhances safety in the workplace, minimizing the risk of accidents during production.

The efficiency of cable manufacturing processes has significantly improved due to advancements in key technologies. Among these, automation and smart machinery play a pivotal role. Automated cable manufacturing systems, equipped with sensors and machine learning algorithms, enhance precision in production lines, reducing waste and increasing output quality. A recent report by MarketsandMarkets indicates that the global cable manufacturing market is projected to reach $233 billion by 2025, driven largely by the integration of these smart technologies.

Another critical technology is the use of advanced materials and coatings, which improve durability and performance while streamlining production. Innovations in polymer chemistry allow for the development of lighter, more flexible wires that require less energy to produce. A study by Grand View Research highlights that these material advancements can lead to a 25% reduction in production costs, positively impacting profit margins across the board.

**Tips:** To maximize efficiency, manufacturers should consider investing in training for their workforce to ensure that they are well-versed in operating and troubleshooting advanced machinery. Regular maintenance of equipment is also essential to minimize downtime and maintain optimal production rates. Moreover, incorporating real-time data analytics can provide insights that drive continuous improvement in manufacturing processes.

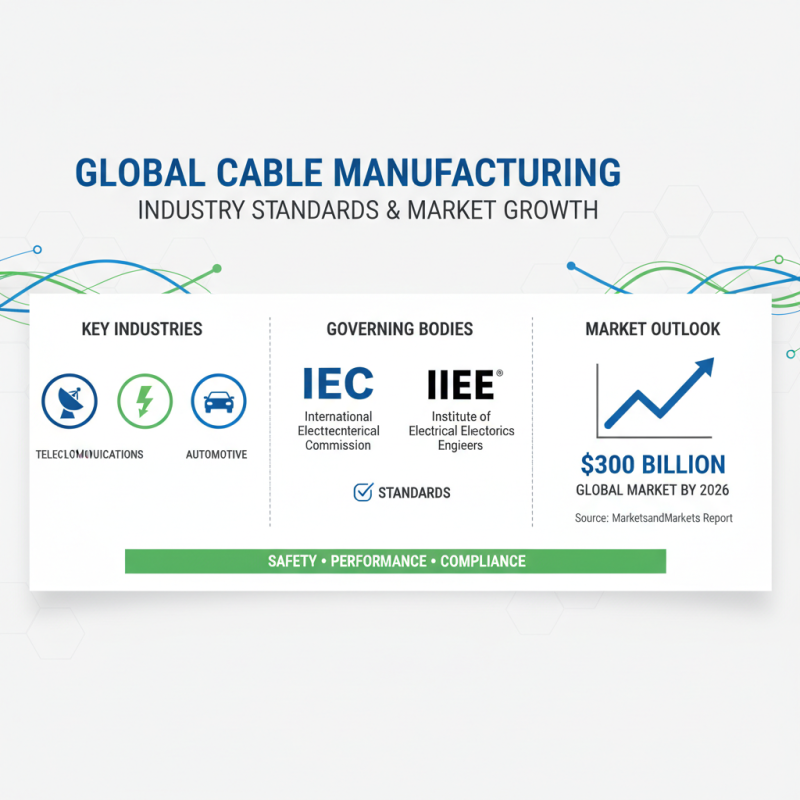

The manufacturing of cables plays a crucial role in various industries, including telecommunications, energy, and automotive. The intricate process of cable production is governed by a series of industry standards and regulations that ensure safety, performance, and environmental compliance. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are two primary bodies that establish guidelines for cable manufacturing. According to a report by MarketsandMarkets, the global cable manufacturing market is expected to reach $300 billion by 2026, highlighting the significance of adhering to these standards to meet growing demands.

The regulations impacting cable manufacturing machines focus on quality control and environmental sustainability. For instance, the European Union's RoHS (Restriction of Hazardous Substances) directive limits the use of specific hazardous materials in electrical and electronic equipment, pushing manufacturers to adopt cleaner technologies and materials during the production process. Furthermore, the adoption of ISO 9001 standards for quality management systems ensures that manufacturers apply consistent practices, leading to superior product quality and customer satisfaction. According to a survey conducted by the American National Standards Institute (ANSI), about 60% of manufacturers reported improved operational efficiency after implementing these standards, demonstrating the critical role they play in the overall performance of cable manufacturing machines.

The future of cable manufacturing machines is set to embrace advanced technologies that enhance efficiency and productivity. As the industry evolves, smart manufacturing processes such as automation, IoT integration, and data analytics are becoming increasingly prevalent. These innovations enable manufacturers to monitor production in real time, optimize machine performance, and reduce downtime. By leveraging predictive maintenance, companies can also anticipate equipment failures before they happen, ensuring smoother operations and less interruption.

Tips: Regular training for operators on new technologies is essential to maximize the benefits of these advancements. Encouraging a culture of continuous improvement can further lead to identifying additional efficiencies within the manufacturing process.

Furthermore, sustainability trends are influencing the design and operation of cable manufacturing machines. Manufacturers are exploring eco-friendly materials and energy-efficient processes to reduce their carbon footprint. Innovations such as energy recovery systems and the use of renewable energy sources will likely shape the landscape of cable production in the coming years.

Tips: Engaging in partnerships with research organizations can provide insights into sustainable practices that can streamline operations while contributing to environmental goals. Companies should also consider investing in technology that allows for waste reduction throughout the production cycle.