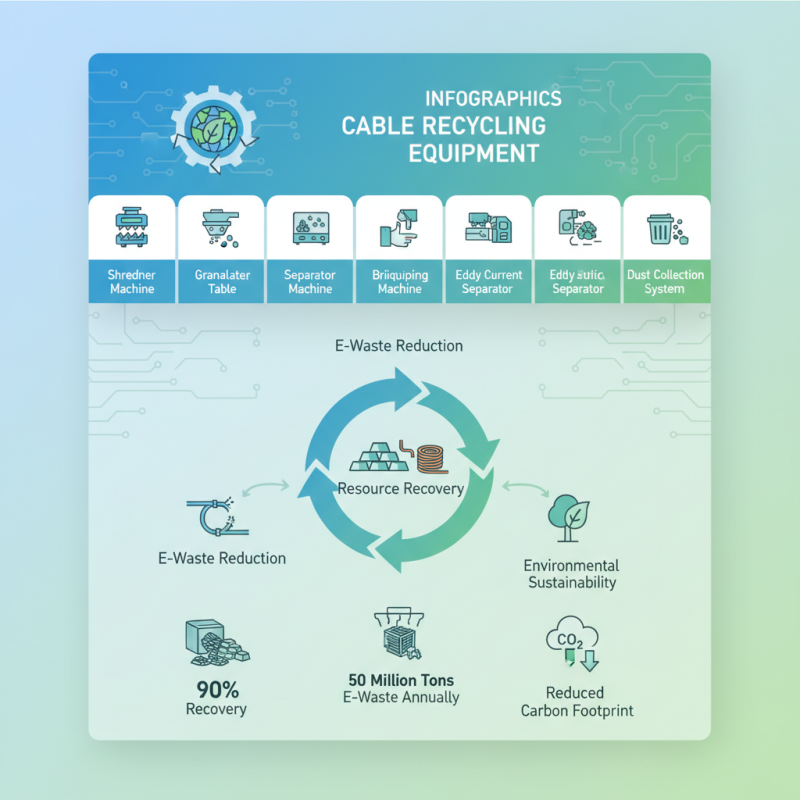

The growing concern for environmental sustainability has prompted various industries to seek effective solutions for waste management, particularly in the recycling of cables, which often contain valuable metals such as copper and aluminum. According to recent industry reports, improper disposal of electronic waste, including cables, contributes to over 50 million metric tons of e-waste generated globally each year, resulting in significant environmental harm and resource loss. This underscores the necessity of investing in advanced Cable Recycling Equipment to mitigate these challenges.

The evolution of cable recycling technology has led to the development of sophisticated machinery designed to efficiently separate and recover these precious materials while reducing harmful emissions. Estimates indicate that with the right equipment, businesses can recover up to 90% of usable materials from disposed cables, translating into substantial economic benefits and a decreased carbon footprint. As the demand for sustainable practices grows, understanding the best options available in the market becomes crucial for organizations looking to enhance their recycling capabilities. This article will explore the top 10 cable recycling equipment solutions that pave the path toward a more sustainable future in waste management.

Cable recycling is crucial for promoting sustainability and reducing environmental impact. As technology advances, the accumulation of discarded cables and wires has increased significantly, leading to a pressing need for effective disposal solutions. Recycling these materials not only conserves natural resources but also reduces pollution caused by improper disposal methods. By reclaiming valuable metals like copper and aluminum, we can contribute to a circular economy, minimizing waste and making the most of our existing resources.

When considering cable recycling, it's essential to choose the right equipment to ensure efficiency and sustainability. Investing in advanced cable recycling machines can streamline the process, enabling the separation of various materials with minimal energy consumption. Additionally, proper training for staff handling these materials is vital; it ensures safety and maximizes the potential for reclaiming reusable materials.

**Tips for effective cable recycling:**

1. Make sure to sort cables by material type before recycling to enhance the efficiency of the process.

2. Partner with certified recycling facilities that comply with environmental regulations to ensure responsible disposal.

3. Stay informed about local recycling programs and incentives that can help minimize costs associated with cable waste management.

| Equipment Type | Processing Capacity (kg/h) | Power Consumption (kW) | Weight (kg) | Estimated Cost ($) |

|---|---|---|---|---|

| Cable Stripping Machine | 300 | 5 | 150 | 2000 |

| Granulator | 500 | 15 | 400 | 5000 |

| Cable Chopper | 200 | 8 | 250 | 3500 |

| Magnetic Separator | 150 | 3 | 100 | 1500 |

| Wire Drawing Machine | 250 | 10 | 200 | 3000 |

| Wire Stripper | 100 | 4 | 75 | 1200 |

| Recycling Plant | 2000 | 50 | 3000 | 75000 |

| Shredder | 800 | 25 | 1500 | 6500 |

| Copper Wire Recycling Machine | 400 | 12 | 500 | 4500 |

| Plastic Recycling Machine | 600 | 20 | 800 | 6000 |

When it comes to sustainable disposal, investing in the right cable recycling equipment is crucial. The market offers a variety of types designed to handle different aspects of cable recycling. Popular options include granulators, which efficiently shred cables for easier processing, and wire strippers, which help separate insulation from metals. Additionally, there are cable balers that compact processed materials for simpler transport and storage.

Tips: Always choose equipment that is compatible with the volume of cables you handle. For those dealing with large quantities, a high-capacity granulator would be ideal to boost productivity. Also, consider the versatility of the machines; multifunctional equipment can save costs and space.

Another essential category is cable recycling plants, which integrate multiple functions into a single system, streamlining the recycling process. Automated systems are increasingly popular, reducing manual labor and improving efficiency. Remember to check for energy-efficient models, as these not only lower operational costs but also align with sustainable practices.

When choosing cable recycling equipment, there are several key features to consider to ensure efficient and sustainable disposal. Firstly, look for machines that offer high processing capacity, which allows for a greater volume of cables to be recycled in a shorter amount of time. This is particularly important for businesses dealing with large quantities of wiring and cables. Additionally, energy efficiency should be a priority; equipment that uses less energy can significantly reduce operational costs while supporting eco-friendly practices.

Tips for selecting the right cable recycling equipment include assessing the machine's versatility. Opt for models that can handle various types of cables, including those with different insulation materials. This flexibility can save time and resources, as you won’t need separate machines for different cable types. Furthermore, consider the machine's safety features. Advanced equipment should include mechanisms such as automatic shut-off and protective shields to ensure operator safety during the recycling process.

Lastly, ensure the equipment is easy to maintain and operate. User-friendly interfaces and straightforward maintenance protocols can minimize downtime and promote a more efficient recycling workflow. Investing in high-quality cable recycling equipment with these top features will not only streamline your operations but also contribute to a more sustainable approach to waste management.

In the quest for sustainable waste management, the cable recycling industry has seen significant innovations in recent years. A report by Global Industry Analysts projected that the global cable recycling market would reach approximately $10.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is attributed to heightened awareness of environmental issues and the increasing availability of advanced recycling equipment.

When evaluating the best cable recycling solutions, several factors are critical: efficiency, recovery rates, and the ability to handle various material types. Equipment like granulators and wire strippers not only streamline separation processes but also enhance the recovery of valuable metals like copper and aluminum. For instance, a recent case study highlighted that modern cable granulators achieve metal recovery rates exceeding 99%, significantly improving the profitability of recycling initiatives. Moreover, the integration of automated systems in cable sorting has reduced labor costs and increased operational safety, making these solutions both economically and environmentally sound choices.

The comparative analysis of these technologies reveals that investing in high-quality recycling equipment is essential for both large-scale industries and smaller enterprises looking to contribute to sustainable practices. With regulations tightening around electronic waste and a growing demand for recycled materials, businesses that embrace advanced cable recycling solutions stand to benefit significantly, positioning themselves as leaders in the circular economy.

The sustainability and economic impact of cable recycling equipment are crucial as the world shifts towards more eco-friendly waste management practices. According to a report by the International Solid Waste Association, cable recycling can potentially recover up to 90% of the materials contained within discarded cables. This includes valuable metals like copper and aluminum, which can be reused in manufacturing, significantly reducing the demand for virgin materials. The successful implementation of advanced cable recycling technologies not only conserves resources but also mitigates the environmental hazards posed by improper disposal of electrical waste.

Moreover, the economic benefits of investing in cable recycling equipment are substantial. The Global Circular Economy report estimates that the cable recycling industry could generate revenue of approximately $8 billion by 2025, as companies increasingly seek sustainable disposal solutions. The reduction in landfill costs and the potential to recover high-value materials contribute to this burgeoning market. Additionally, job creation within the recycling sector is projected to rise, aligning with global green economy initiatives. As awareness grows and technology evolves, businesses stand to gain both economically and environmentally from adopting effective cable recycling practices.

This chart displays the estimated capacity of various types of cable recycling equipment, showcasing their efficiency in sustainable disposal solutions. Each bar represents the potential handling capacity, measured in kilograms per hour, of different machinery utilized in the cable recycling industry.