In the dynamic landscape of the cable manufacturing industry, selecting the right Cable Manufacturing Machines is a critical decision that can profoundly impact production efficiency and product quality. As John Thompson, a leading expert in cable technology and engineering, aptly stated, "The right machine not only enhances productivity but also ensures the consistency and reliability of the end product." With a myriad of options available, manufacturers must carefully assess their specific production requirements and technological advancements to find the optimal solutions.

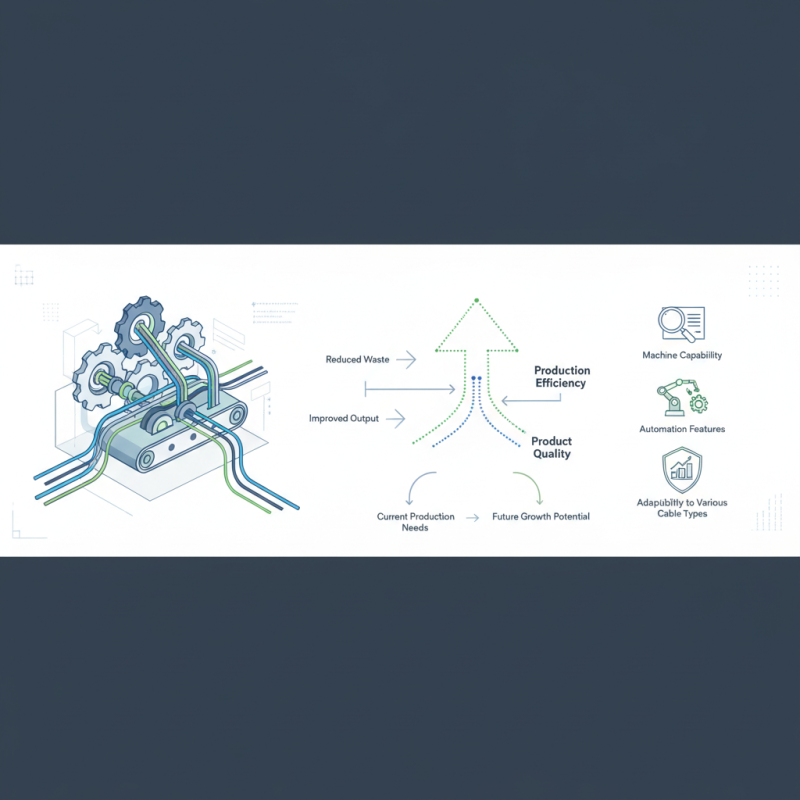

The versatility and precision of modern Cable Manufacturing Machines can significantly streamline production processes, reducing waste and improving output. Factors such as machine capability, automation features, and adaptability to various cable types play crucial roles in this selection process. As manufacturers strive to meet rising demand and stringent quality standards, a strategic approach in choosing the right equipment becomes more essential than ever.

Ultimately, the decision-making process surrounding the acquisition of Cable Manufacturing Machines requires a thorough evaluation of both current production needs and future growth potential. By investing in the right technology, manufacturers can not only enhance their operational efficiencies but also position themselves competitively in the ever-evolving market.

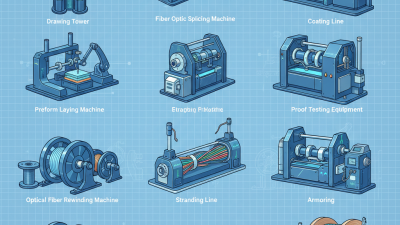

When selecting cable manufacturing machines, it's crucial to understand the variety of machines available and how they cater to different production needs. The primary categories of cable manufacturing machines include extrusion lines, wire drawing machines, and stranding machines.

Extrusion lines are typically used for insulating wires, allowing for precise control over the thickness and quality of the insulation. Wire drawing machines, on the other hand, reduce the diameter of the wire and increase its length, essential for producing raw materials in various gauges.

Tips: When assessing your production requirements, consider factors such as the materials you will use, the desired output rate, and the specific cable types you intend to manufacture. This assessment will help you align your equipment choices with your operational goals.

Moreover, stranding machines play a vital role in twisting together multiple wires to form stranded conductors, often seen in power cables. It's essential to choose a stranding machine that offers the flexibility to produce various strand configurations, depending on the end application.

Investing in versatile machines can help enhance your production capabilities and adapt to changing market demands.

Tips: Always evaluate the technical specifications and compatibility of the machines with your existing production setup. Manufacturer support and availability of spare parts are also key considerations to ensure long-term operational efficiency.

When selecting cable manufacturing equipment, it is essential to consider several key factors to align with your production needs. One of the foremost aspects is the type of cable being produced. Different cables, such as telecommunications, power, or fiber optic cables, require specialized machinery with varying capabilities. According to a recent report from MarketsandMarkets, the global wire and cable manufacturing market is expected to grow from $223.6 billion in 2021 to $268.5 billion by 2026, highlighting the significance of investing in machinery that can cater to diverse and evolving product requirements.

Another crucial factor is the machine's production capacity and efficiency. High throughput rates are essential for meeting market demands, but efficiency also directly influences operational costs. Data from Grand View Research indicates that advancements in technology, such as automation and IoT integration, are drastically improving production efficiencies. Selecting machines that offer real-time monitoring and predictive maintenance can significantly enhance uptime and minimize downtime, thus optimizing overall productivity and cost-effectiveness.

Furthermore, the flexibility of the equipment plays a vital role in production adaptability. As market trends shift and new cable types emerge, machines that can easily accommodate changing requirements—such as adjustable settings for various wire sizes or materials—become invaluable. According to a report by Technavio, 45% of manufacturers now prioritize flexibility in machinery to stay competitive. Considering these factors will ensure that businesses not only meet current production needs but also remain agile for future demands.

| Factor | Description | Importance | Example Machines |

|---|---|---|---|

| Production Capacity | Assess the maximum output of the machine to meet demand. | High | High-speed extrusion lines |

| Material Compatibility | Ensure the machine can process the types of materials you use. | Critical | Multi-material extrusion systems |

| Ease of Use | Look for intuitive controls and user-friendly interfaces. | Moderate | Automated cable production lines |

| Maintenance Requirements | Consider how often the machine needs servicing and parts replacement. | High | Robust industrial cable machines |

| Cost of Ownership | Evaluate the total expense over the machine's lifespan, including energy and operational costs. | Critical | Energy-efficient cable machinery |

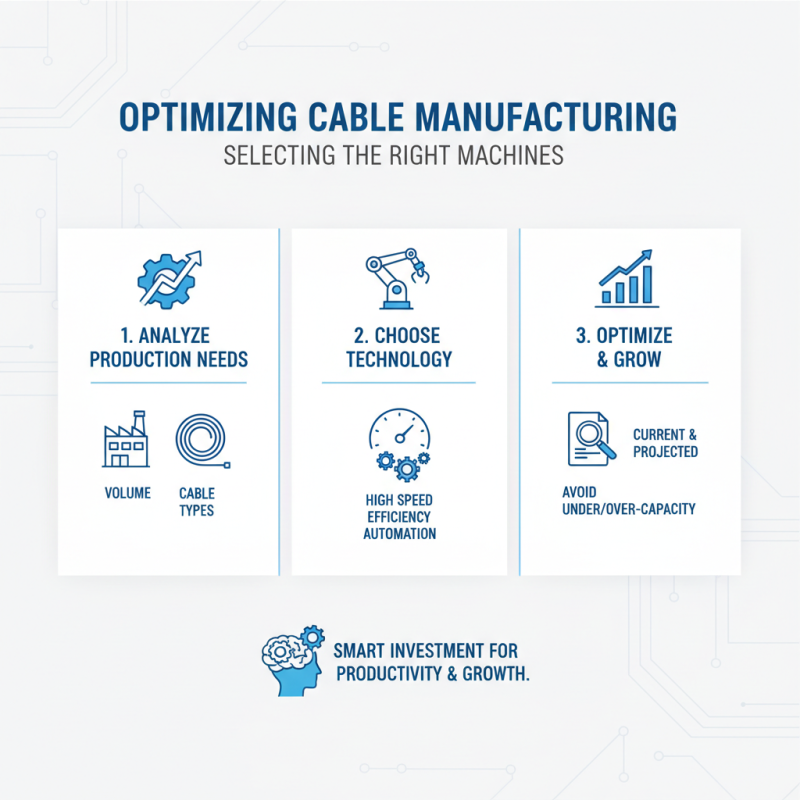

When selecting the best cable manufacturing machines, a crucial first step is to analyze your production capacity needs. Understanding the volume of production and the types of cables required will directly influence the machinery you choose. For instance, if your operation necessitates high output levels to meet demand, investing in advanced automated machines that offer high speed and efficiency can tremendously enhance productivity. It’s essential to evaluate both current and projected production requirements to avoid underutilization or overcapacity.

Additionally, assessing the specific manufacturing processes involved in cable production is vital. Different machines serve various roles, from wire drawing and stranding to sheathing and insulating. By comprehensively understanding each process's demands, such as the necessary material specifications and operational precision, you can select machines that align closely with your technical requirements. This alignment not only optimizes production workflows but also minimizes potential delays and maintenance issues, thereby enhancing overall operational efficiency. Choosing the right machines based on a detailed analysis of production capacity ensures that your investment supports sustainable growth in a competitive market.

In the rapidly evolving field of cable manufacturing, technological innovations play a crucial role in enhancing production efficiency and product quality. Modern cable manufacturing machines are now equipped with advanced features such as automated monitoring systems and real-time data analytics. These innovations not only streamline the production process but also allow manufacturers to quickly adapt to changing market demands and product specifications. By utilizing sophisticated software and machine learning algorithms, manufacturers can optimize production runs, minimize downtime, and significantly reduce waste.

Moreover, the introduction of environmentally friendly production techniques has transformed cable manufacturing machinery. Innovations such as energy-efficient motors and recyclable materials contribute to sustainable manufacturing practices. These developments enable companies to reduce their carbon footprint while maintaining high levels of productivity. Additionally, smart manufacturing technologies, including the Internet of Things (IoT), are enhancing machine connectivity and control, leading to more precise manufacturing processes. As cable manufacturers embrace these technological advancements, they are better positioned to meet the challenges of a competitive landscape and the demands of a more eco-conscious consumer base.

When selecting cable manufacturing machines, assessing cost-effectiveness and return on investment (ROI) is crucial.

Start by analyzing the initial purchase cost against the machine's long-term operational efficiency. Machines that may have a higher upfront cost often come with advanced technology that can reduce labor expenses and minimize material waste. This investment can lead to substantial savings over time, enabling a more profitable production process.

Additionally, consider the machine's production capacity and versatility. A machine capable of producing various cable types can adapt to changing market demands, providing greater opportunity for sales and revenue. Evaluate the total cost of ownership, which includes maintenance, energy consumption, and potential downtimes. Investing in reliable machines with lower maintenance needs can significantly enhance ROI, as they minimize production disruptions and ensure consistency in output quality.

Conducting a thorough cost-benefit analysis will help in making a well-informed decision that aligns with your production goals.