Choosing the right Cable Recycling Machines can be daunting. Industry expert John Smith emphasizes, "The right machine can significantly enhance your recycling efficiency." This statement highlights the importance of making informed choices.

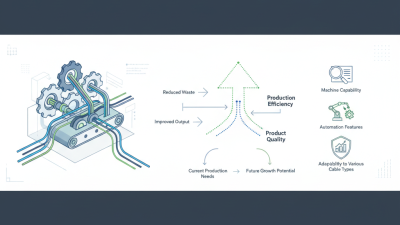

A variety of factors must be considered. The capacity of the machine is crucial. Larger machines handle bigger volumes, but they require more space. Smaller machines might fit snugly in tighter locations, yet they often process less. Additionally, the technology within these machines varies. Some offer advanced features that can improve output and reduce waste.

Investing in Cable Recycling Machines without doing thorough research can lead to regret. Many businesses find themselves with equipment that does not meet their needs. It's essential to carefully assess your requirements to avoid such pitfalls. Each part of the decision-making process requires deep reflection.

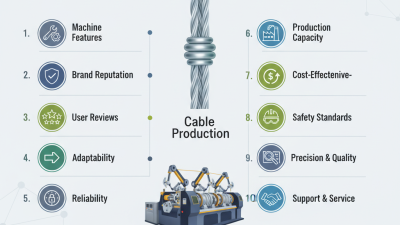

When choosing a cable recycling machine, it’s important to understand the different types available. These machines vary in design and function. They are primarily categorized into three types: granulators, strippers, and whole cable recycling systems. Granulators break down the cable into small pieces, which can then be further processed. Strippers remove insulation and protectors, yielding valuable copper and aluminum, often fetching good prices in the market. Whole systems automate much of the process but require a larger investment.

Data from industry reports shows that cable recycling can yield significant profits. For example, copper prices have fluctuated, reaching up to $10,000 per ton at peak times. Market growth for cable recycling is projected to rise by 4.5% annually. This highlights the importance of selecting a machine that fits operational needs while maximizing recovery rates.

Tips: Assess your output needs before purchasing. If your volume is low, a cable stripper may suffice. For higher volumes, consider investing in a granulator or whole system. Remember that maintenance costs can affect long-term savings. While higher-end machines offer efficiency, they may not always justify the expense. Evaluate your budget alongside potential returns to ensure the best choice.

When selecting the right cable recycling machine, several key features should be at the forefront of your decision-making process. Efficiency is critical; machines should effectively separate copper from plastic. Industry reports show that efficient systems can recover up to 98% of copper from cables. This statistic represents significant economic benefits, especially when copper prices fluctuate.

Durability is another vital aspect. Machines should be built to withstand continuous operation. Many operators face wear and tear issues, resulting in costly downtime. Choosing machines that are designed with high-quality materials can mitigate these problems. Additionally, ease of use should be considered. Operators often encounter difficulties with complex controls, leading to errors in processing. Streamlined and intuitive controls can enhance productivity significantly.

Finally, consider the machine's maintenance requirements. Some models demand frequent servicing, which may not be feasible for all businesses. Regular maintenance can add unexpected costs. An ideal machine should be reliable with minimal maintenance, allowing operators to focus on production instead of repairs. Reflecting on these features can help align your choice with operational needs.

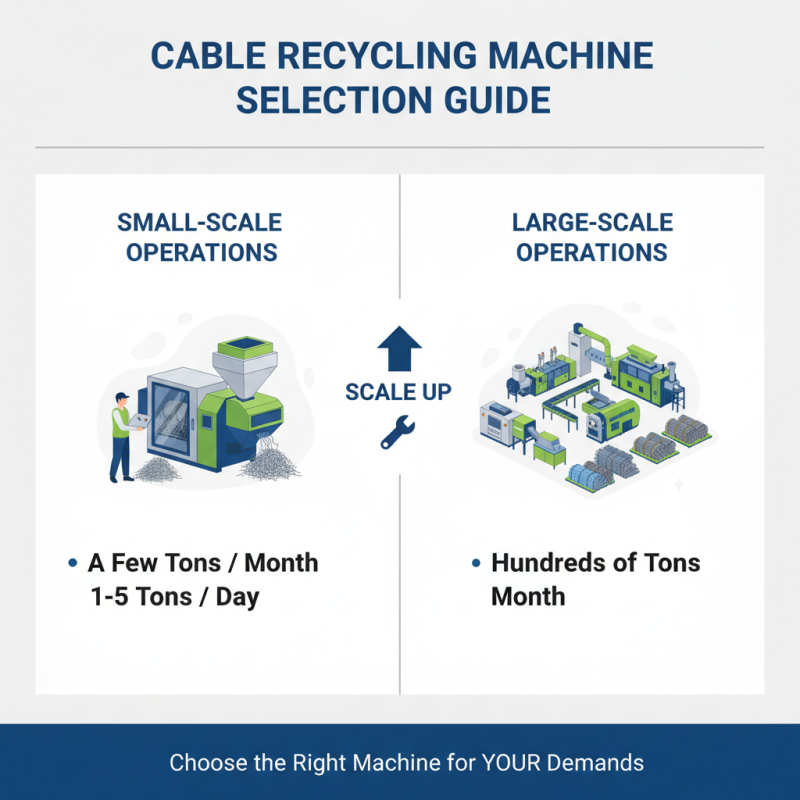

Choosing the right cable recycling machine begins with assessing your operational scale. Small-scale operations may process a few tons of cables per month. In contrast, larger operations need to handle hundreds of tons. According to industry reports, a small facility can recycle around 1-5 tons daily, making it crucial to choose machines that meet this demand.

For small operations, simplicity is key. Compact machines are often easier to operate and cost-effective. They require less space and can efficiently handle mixed cable types. However, they might be limited in processing speed. On the other hand, large-scale operations benefit from high-capacity machines. These can shred thousands of pounds of cable every hour. This can lead to faster returns on investment.

Tips: Always review your expected volume before purchasing. Ensure the machine has the necessary throughput. Also, consider maintenance needs. Machines that are too complex can lead to downtime. Investing in user-friendly equipment may save costs in the long run. Remember, the right choice balances capability and maintainability.

When considering cable recycling machines, understanding environmental regulations is crucial. Different regions have varying compliance requirements. Failing to meet these can lead to costly penalties. Regulations may dictate the types of materials recyclable by certain machines. These rules evolve, reflecting changes in environmental policies.

Evaluating machine capabilities against these regulations is vital. Some machines might be efficient but not compliant. Being aware of local laws will help narrow down options that meet the set standards. It's imperative to check for certifications. Often, eco-friendly guidelines suggest selecting machines that minimize energy use and emissions.

Be wary of machines marketed as wholly compliant. Transparency varies among manufacturers. Some may omit critical details. Always verify claims through independent sources. It can be challenging to find the perfect balance between cost and compliance. Sometimes, clients prioritize price over environmental impact, which could lead to issues later. Reflecting on long-term consequences is essential in this decision-making process.

When considering cable recycling machines, cost analysis becomes crucial. Start by assessing your budget. Different machines come with a wide range of price tags. Cheaper models may seem appealing, but they might lack durability. Investing a bit more could save you money long-term.

Look beyond just the purchase price. Maintenance costs can add up. Some machines require frequent repairs or replacement parts. This can drastically affect your overall expenses. Evaluate warranties and customer support options too. A reliable service can help reduce long-term costs.

Think about capacity needs. A machine that's too small can slow down operations. Conversely, one that's too large may waste resources. Finding the right fit is essential. Consider energy efficiency as well. Machines that consume less energy can lead to significant savings. Always balance initial costs with potential operational expenses.