The global shift towards sustainable practices has led to an increased focus on recycling technologies, particularly in the realm of metal recovery. Among these technologies, the Copper Wire Granulator Machine stands out as an essential tool for efficiently processing discarded copper wires. According to a report by Market Research Future, the global market for copper recycling is projected to reach $8.45 billion by 2025, driven by rising demand for recyclable materials and stringent environmental regulations. This machine allows recyclers to maximize their output while minimizing environmental impact, making it an invaluable asset in the drive towards a circular economy.

Industry expert Dr. Emily Carter, a leading figure in materials recycling, emphasizes the significance of this technology, stating, "The Copper Wire Granulator Machine not only symbolizes innovation in waste processing but also reflects our commitment to reducing landfill waste and improving resource recovery." These machines operate by separating copper from insulation without causing damage, resulting in pure copper granules that are highly valued in various manufacturing processes. As the need for efficient waste management and resource recovery continues to grow, understanding the workings and benefits of Copper Wire Granulator Machines becomes increasingly important for stakeholders in the recycling industry.

A copper wire granulator machine is a specialized piece of equipment designed to process scrap copper wires. Its primary function is to separate copper from the insulating materials, enabling the recovery of valuable copper while reducing waste. This machine operates by feeding the wire into a series of grinding and separation processes, ultimately resulting in pure copper granules and waste insulation material.

The operation of a copper wire granulator typically begins with the wires being fed into a crushing unit. The machine breaks down the wires into smaller fragments, allowing for easier processing. Following this initial step, the fragments are subjected to a series of sieving and air separation techniques. These processes utilize differences in weight and size to effectively separate the copper from non-metallic materials, ensuring high purity in the final product. This granulator not only enhances the recycling of copper but also contributes to more sustainable waste management practices.

| Feature | Description |

|---|---|

| Function | Processes copper wire and cables into granulated copper and plastic. |

| Components | Wire feeder, granulator, vibrating separation table, and dust collector. |

| Efficiency | Can process up to 1,000 kg of copper per hour, depending on model. |

| Applications | Used in recycling facilities, scrapyards, and metal recovery operations. |

| Environmental Impact | Helps in reducing electronic waste and recovering valuable metals. |

| Advantages | Maximizes copper recovery, minimizes labor costs, and enhances profitability. |

| Maintenance | Regular check-ups required for efficient operation and longevity. |

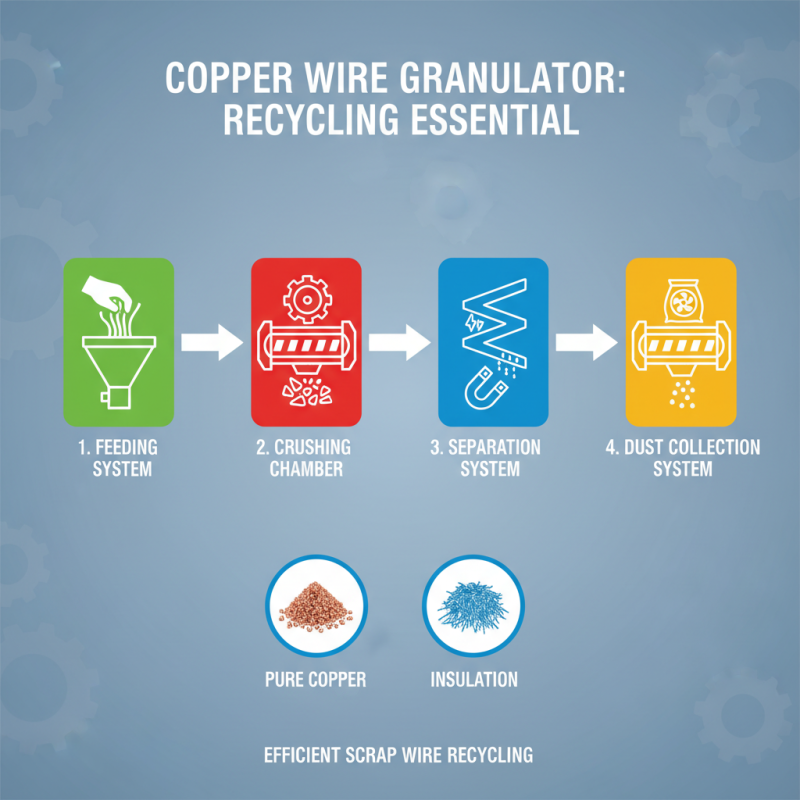

A copper wire granulator machine is designed to efficiently process scrap copper wire and cable, making it an essential tool in recycling operations. The machine primarily comprises several key components, each playing a pivotal role in the granulation process. These components include the feeding system, crushing chamber, separation system, and dust collection system.

The feeding system is responsible for introducing the copper wire into the machine, where it is precisely controlled to ensure optimal processing. Once inside, the crushing chamber breaks down the wire into smaller pieces using sharp blades, which is crucial for the next stage. Following the crushing process, the separation system comes into play. This system typically employs air or vibrating technologies to differentiate between copper and insulation materials effectively, allowing for the recovery of pure copper granules. Additionally, the dust collection system works in tandem to minimize environmental impact by capturing any non-metallic debris and fine particles generated during the granulation process.

These components work synchronously, enabling the copper wire granulator machine to achieve high efficiency and a high recovery rate of copper material. The seamless integration of these parts ensures that copper recycling operations can be both economical and environmentally sustainable, contributing to the circular economy.

Copper Wire Granulator Machines are essential for recycling copper from old wires. The process begins with feeding raw materials into the machine's input. As the copper wires and insulation materials enter the granulator, they are subjected to crushing and grinding, which separate the metal from the non-metal components. This is accomplished through a series of cutting blades and screens, allowing for precise sizing of the granulated copper.

Once the materials are ground down, air classification is employed to separate the copper granules from the plastic or rubber insulation. The granules are then collected in a separate container, ensuring a clean and pure copper output. Advanced machines may also utilize a magnetic separator to further enhance the purity of the recycled copper.

Tips: When operating a copper wire granulator, ensure that the wires are stripped of connectors and excess parts, as these can hinder the efficiency of the machine. Additionally, regularly check and maintain the blades for optimal performance and longevity. Lastly, it's advantageous to sort the wires by type and copper content before processing, as this can significantly improve the end product's quality.

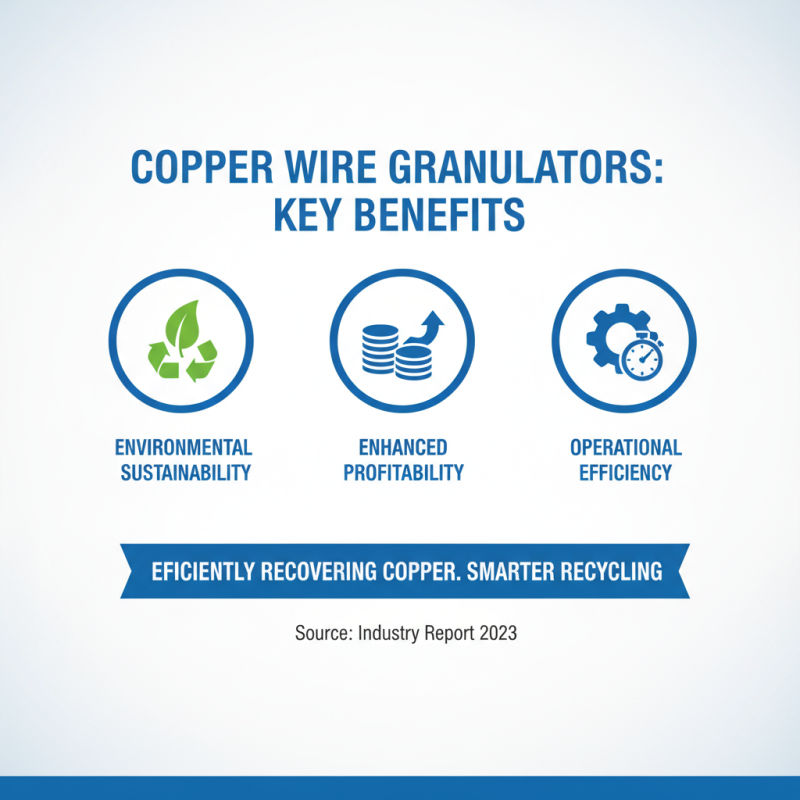

Copper wire granulators are essential tools in the recycling industry, particularly for extracting copper from scrap wire. By effectively separating the metal from its insulation, these machines contribute significantly to efficient recycling processes. The benefits of using copper wire granulators extend beyond just copper recovery; they promote environmental sustainability, enhance profitability, and improve operational efficiency for recycling facilities.

One of the key advantages of copper wire granulators is their ability to maximize the recovery of valuable metals while minimizing waste. By converting scrap copper wire into clean, marketable granules, these machines reduce the amount of material that ends up in landfills. Additionally, the automated nature of granulators speeds up the recycling process, which can lead to increased productivity and reduced labor costs for businesses.

Tips: When investing in a copper wire granulator, consider the machine's processing capacity and efficiency. Opt for a model that is capable of handling different types of wire, as this versatility can significantly enhance your operation. Regular maintenance of the granulator is also essential to ensure optimal performance and longevity, preventing unexpected downtime that could affect productivity.

When evaluating the efficiency of copper wire granulator machines, industry standards and metrics play a critical role in assessing their performance. One key metric is the separation rate, which indicates how effectively a granulator can separate copper from plastic insulation. According to a report by the Institute of Scrap Recycling Industries (ISRI), the top-performing machines in the industry can achieve separation rates exceeding 99%, which significantly enhances the purity of the recovered copper. This level of efficiency not only maximizes profitability for recycling operations but also aligns with environmental sustainability goals by ensuring higher quality raw materials are diverted from landfills.

Another important efficiency metric is the processing capacity of granulator machines. Many machines on the market today are designed to process between 1,000 to 3,000 pounds of material per hour. When considering the economic viability of a recycling operation, this throughput is crucial, as it directly impacts operational costs and workforce allocation. A study published in Recycling Today indicates that facilities with higher throughput rates can improve their return on investment (ROI) by as much as 40% compared to those using older, less efficient technology. Adhering to industry standards not only boosts operational efficiency but also ensures compliance with environmental legislation, fostering a more responsible recycling industry.