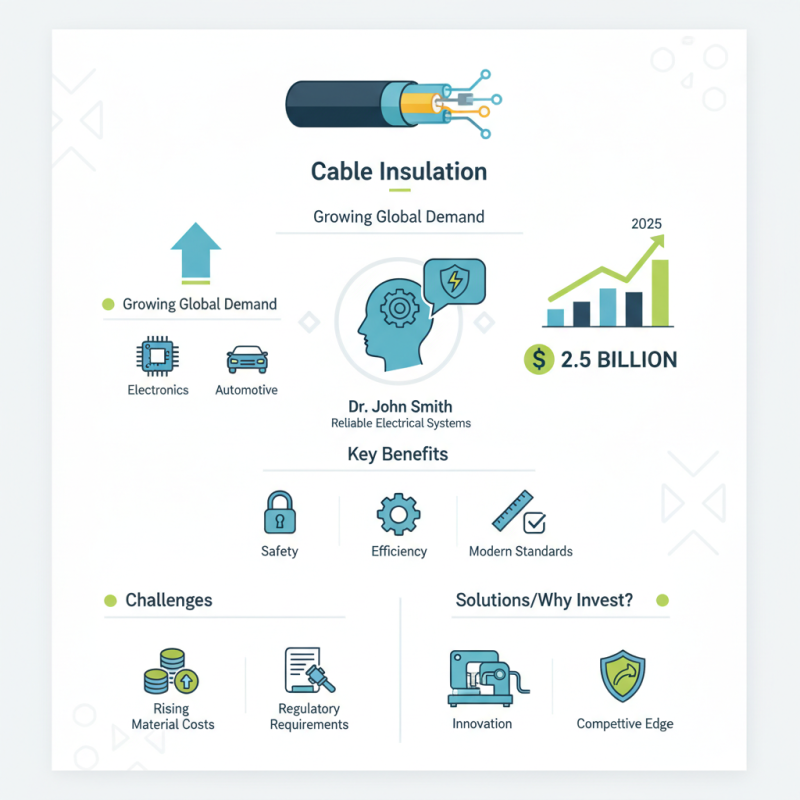

In today's fast-paced manufacturing landscape, Cable Insulation Machines are vital. The global demand for these machines is surging, driven by increased production needs in the electronics and automotive sectors. According to a report by MarketsandMarkets, the market for cable machinery is expected to grow significantly, reaching $2.5 billion by 2025. This growth emphasizes the importance of efficient insulation processes.

Dr. John Smith, a renowned expert in cable technology, once stated, "Cable Insulation Machines are the backbone of reliable electrical systems." His insight reinforces the significance of these machines. They ensure safety and efficiency in manufacturing cables that meet modern standards. As technologies evolve, manufacturers face challenges, including rising material costs and regulatory requirements. The right insulation machine can address these issues, but not all manufacturers have adapted yet.

While many companies recognize the value, some remain hesitant to invest. Embracing innovation is crucial for survival. Therefore, understanding the importance of Cable Insulation Machines is essential for modern manufacturers seeking to remain competitive.

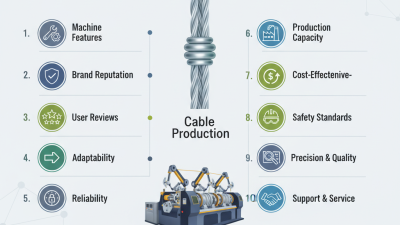

Cable insulation machines play a crucial role in modern manufacturing. They enhance efficiency by providing consistent and precise insulation. This precision reduces production errors and minimizes waste, resulting in cost savings. Manufacturers can rely on these machines for quick turnaround times on large orders.

The speed of cable insulation processes has improved significantly. Faster production allows manufacturers to meet higher demands in the market. However, some may overlook the importance of regular maintenance. Neglecting this can lead to breakdowns. These interruptions can cause delays and impact overall productivity.

Moreover, advancing technology in insulation machines introduces new capabilities. Some machines now offer multi-layer insulation options. This flexibility can meet various industry needs. Yet, adapting to new machinery can be overwhelming for some teams. Staff training becomes essential to fully utilize these advanced features. Organizations must invest time and resources to ensure everyone is on board.

Cable insulation machines are vital in modern manufacturing. They enhance efficiency and ensure quality. With the right features, these machines streamline cable production. This brings consistency and reliability to the end product.

One key feature is advanced technology. These machines often use automated systems for precision. They minimize human error and reduce waste. Another important aspect is adjustable settings. Manufacturers can easily customize insulation thickness and materials. This adaptability is crucial for meeting diverse requirements.

Tips: Regular maintenance is essential. It keeps the machines running smoothly and avoids costly downtime. Keep spare parts ready for quick replacements. Also, training operators thoroughly ensures safe and effective usage. Remember, any neglect can lead to significant setbacks. Careful attention to these details can improve production quality and efficiency dramatically.

Cable insulation plays a crucial role in product quality and safety. Proper insulation prevents electrical leakage, protecting both the equipment and users. Poor insulation can lead to failures or hazards. This highlights the need for high-quality insulation processes in manufacturing.

Manufacturers must ensure that insulation is applied uniformly. Gaps or inconsistencies can create risks. A well-insulated cable exhibits better performance and longevity. It minimizes the chances of short circuits or electrical fires. However, achieving high standards in insulation requires constant attention and improvement.

Quality control should not be overlooked. Regular inspections and tests are essential. They help identify potential flaws before reaching the consumer. Investing in cables with superior insulation can enhance overall product reputation. Mistakes in this area can be costly. Customers expect safety and reliability. Failure to deliver on these aspects can damage trust in the brand.

| Dimension | Value |

|---|---|

| Production Efficiency | Increases by up to 30% |

| Defect Rate | Reduced to less than 1% |

| Safety Compliance | Meets all federal safety standards |

| Material Waste | Decreased by 20% |

| Market Demand | Increasing rapidly due to technological advancements |

| Operational Cost Savings | Estimated at 15% annually |

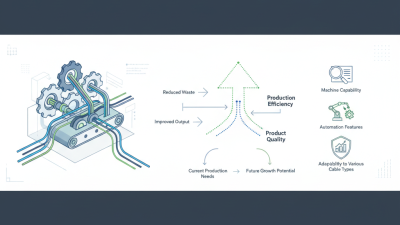

Cable insulation machines play a pivotal role in modern manufacturing. These machines not only enhance efficiency but also significantly reduce costs. According to a recent industry report, companies can save up to 25% on production costs by automating the insulation process. This substantial savings arises from increased speed and reduced labor costs.

Moreover, insulation machines contribute to less material waste. In manufacturing, the average waste percentage can reach 10%. However, with precise insulation technology, this can be reduced to just 3%. This improvement not only lowers production costs but also promotes environmental sustainability. Manufacturers face challenges in balancing quality and cost. Many still rely on outdated methods, risking inefficiency.

The initial investment in advanced insulation machines may seem high. Yet, the return on investment (ROI) becomes apparent within a year through savings and increased output. Analyses show that businesses adopting these machines see an average ROI of 50% within 12 months. As companies strive for competitiveness, adaptation becomes crucial. Neglecting modern technology may lead to falling behind industry standards.

The bar chart above illustrates the annual cost estimates associated with various components in cable insulation manufacturing. The data highlights that material costs dominate the expenses, with labor and production efficiency being critical factors for overall cost-effectiveness. By investing in advanced insulation machines, companies can significantly improve production efficiency and reduce long-term operational costs.

The cable insulation industry is rapidly evolving. In recent studies, the demand for high-performance insulation materials has increased by over 25% in the last five years. Manufacturers are adapting quickly to meet the needs of more sophisticated applications, such as electric vehicles and renewable energy systems. As projects grow in complexity, traditional methods no longer suffice.

Emerging technologies are playing a vital role. The integration of automation and AI in cable insulation processes is becoming commonplace. Reports indicate that 80% of manufacturers are investing in smart machinery to enhance efficiency. However, this shift also raises questions about skills. Workers need training to adapt to these advanced technologies. Not all employees feel ready for this change.

Sustainability is another pressing issue. While new materials are being developed, many lack eco-friendly attributes. Research shows that over 70% of manufacturers are under pressure to reduce their carbon footprint. This challenge is significant. Without proper methods to achieve sustainability, the entire industry risks backlash. Balancing innovation and environmental responsibility is crucial for future success.