In the world of cable production, choosing the right Cable Armoring Machine is crucial. Renowned industry expert, John Smith, emphasized, "The right machine can make or break your project's success." This highlights the machine's role in ensuring quality and efficiency.

Cable armoring is a demanding process. A machine that lacks precision can lead to significant losses. Each component matters, from the design to the operation. A poorly chosen machine may cause delays and increased costs.

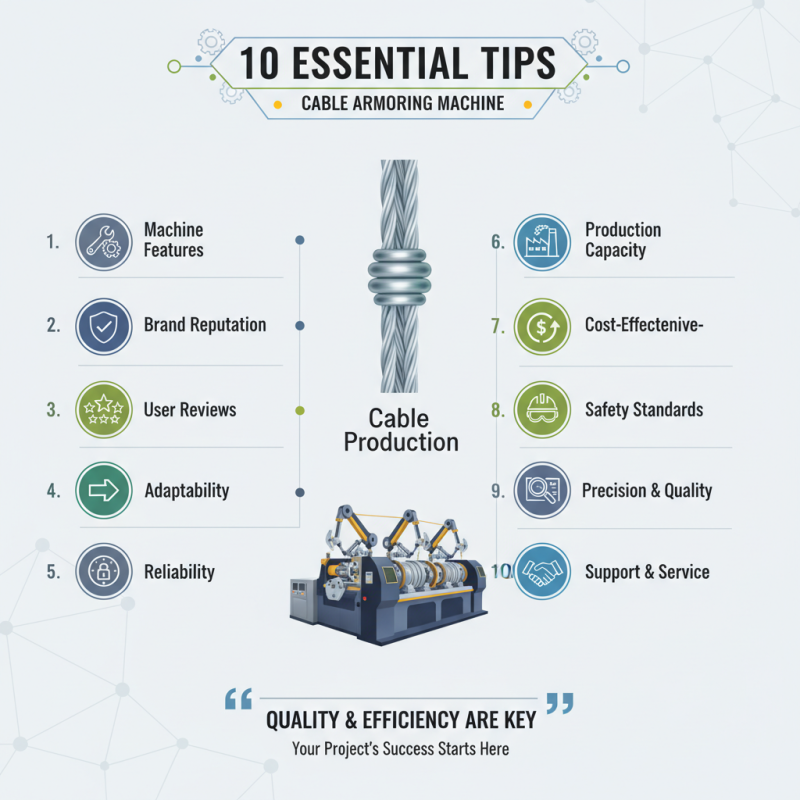

It's essential to reflect on machine features, brand reputation, and user reviews. Will it adapt to changing demands? Is it reliable over time? Take time to weigh these factors carefully. After all, the success of your cable products hinges on this decision.

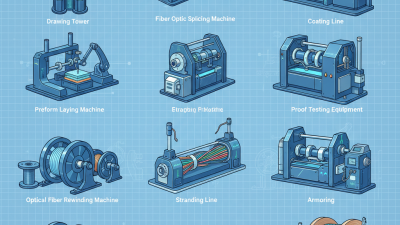

Cable armoring plays a critical role in manufacturing. It protects cables from environmental hazards. These can include physical damage, moisture, and chemical exposure. The right armoring ensures durability and reliability. Without it, cables may fail prematurely. This can lead to costly downtime.

Choosing the right armoring machine is essential. Different projects require different levels of protection. Understanding your specific needs is vital. Not all machines are the same. Some may not meet the demands of your production line. Others could be too complex for your simple requirements. Reflecting on these issues can prevent future headaches.

Investing in the right cable armoring machine can be a tough decision. It requires balancing cost with quality. Misjudging this can lead to waste. It's important to review options carefully. Talk to experienced manufacturers. Gather feedback from your team. This process might reveal flaws in your initial choices. A thoughtful approach can make a significant difference.

When selecting a cable armoring machine, there are key features that demand attention. The machine's capacity is crucial. According to industry reports, a machine with a production capacity of 1,000 meters daily can significantly enhance efficiency. Look for models that boast a high-speed operation. Some machines can process cables at speeds exceeding 250 meters per minute. This speed directly correlates to output.

Another important feature is user-friendly controls. Machines should have an intuitive interface that minimizes the learning curve. Operators should be able to adjust settings easily without extensive training. A report by the International Wire and Cable Industry Association notes that productivity increases by 30% when operators can use machines efficiently.

Next, consider the safety features. Machines with protective housing and emergency stop functions reduce workplace accidents. Despite advances, many machines still lack comprehensive safety controls, leading to potential risks. A reliable machine should provide both quality output and a safe working environment.

Quality assurance features are also essential. Machines equipped with monitoring systems ensure consistent product quality. In instances where quality assurance is weak, issues can arise, leading to costly production delays. Evaluating these features is vital for optimal machine selection.

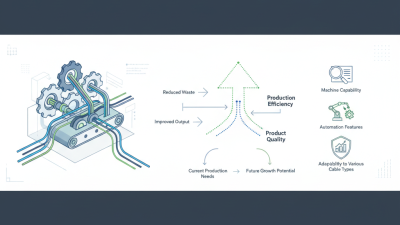

When evaluating the capacity and speed of cable armoring equipment, several factors come into play. The machine’s output rate is crucial. It determines how efficiently the production line operates. A higher speed often improves productivity. But it can also risk compromising safety and quality. Balancing speed with precision is essential.

Capacity is another important factor. You need to assess how many cables the machine can armor in a given time. Too much capacity can lead to underperformance if demand is low. Companies may invest in machines that exceed their needs. This can cause financial strain. Think carefully about your production targets.

Consider the machine’s adaptability as well. Some machines may work well for specific cable types, but struggle with others. Evaluate whether the machine can be adjusted for future needs. Flexibility can save you from making costly upgrades. It’s not always easy to find the right balance between capacity, speed, and versatility. Take the time to analyze your options.

When selecting a cable armoring machine, assessing its build quality and durability is crucial. Look for machines that use high-grade materials. Steel and aluminum components often indicate strength. Weak materials can lead to frequent breakdowns, which costs time and money. Ensure all parts fit together seamlessly to avoid operational issues.

Consider the environment where the machine will be used. It should withstand harsh conditions, such as dust and moisture. Machines designed with protective coatings often have a longer lifespan. Pay attention to wear-resistant features too. However, remember that even the best machines can falter over time. Regular maintenance can help avoid unexpected failures.

It's easy to overlook the importance of user feedback. Reviews from other operators provide insight into a machine's real-world performance. While specifications look great on paper, real experiences tell another story. Be open to feedback and willing to reconsider your choices based on that input. Choosing the right machine is a balance of quality, user experience, and practicality.

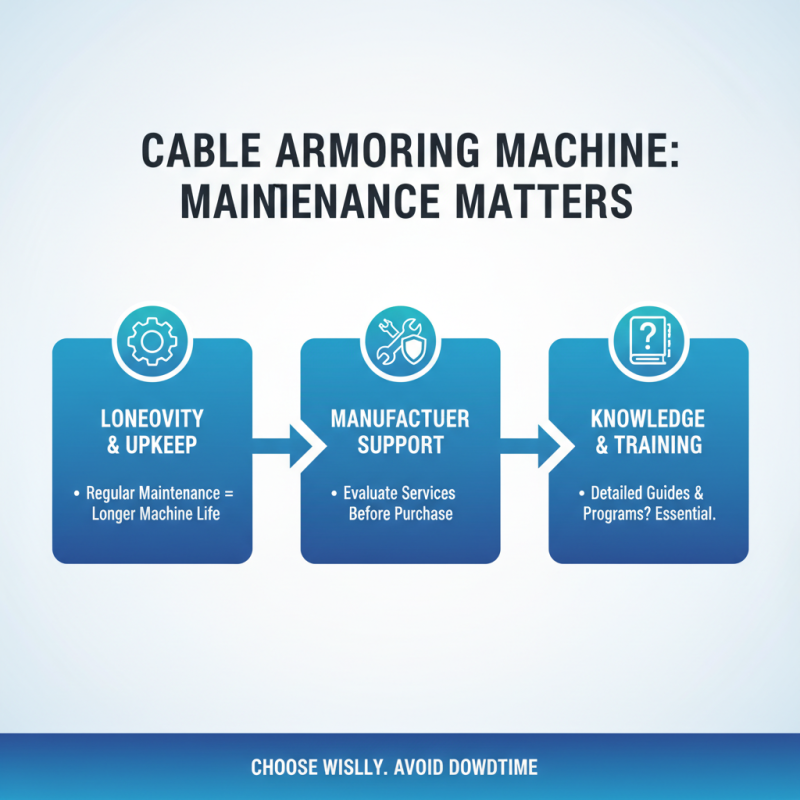

When choosing a cable armoring machine, maintenance support is crucial. A machine’s longevity depends on regular upkeep. Before making a decision, evaluate the manufacturer’s services. Are detailed guides and training programs available? If not, you may face challenges down the line.

Consider the availability of spare parts. Quick access to these components reduces downtime. Check how easy it is to order them. A reliable provider helps ensure that your equipment runs smoothly. Reflect on the technical support offered. Responsive support can make a huge difference when issues arise.

While analyzing your options, prioritize machines known for user-friendly maintenance. This choice can lead to cost savings in the long run. A machine that complicates repairs may become a headache. Investing in an intuitive design could pay off. Research reviews and gather feedback from existing users. Their experiences can reveal potential pitfalls.