In the competitive landscape of cable manufacturing, the efficiency and longevity of machinery heavily rely on the precision of its installation. According to industry expert John Smith, a leading authority in Cable Machinery Installation, “The foundation of optimal machinery performance begins with the installation process—every detail matters.” This notion underscores the importance of a careful and informed approach to cable machinery setup, where even minor oversights can lead to significant operational inefficiencies.

Effective Cable Machinery Installation not only enhances performance but also reduces maintenance costs and downtime. Proper alignment, calibration, and adherence to safety standards are critical components that can directly impact production capabilities and overall profitability. As manufacturers face evolving demands and tighter production schedules, mastering the nuances of installation becomes an imperative for success in the industry.

By understanding key practices and principles inherent in successful Cable Machinery Installation, businesses can secure a competitive edge, ensuring that their operations run smoothly and efficiently. This article will guide you through essential steps and considerations to achieve the optimal performance of your cable machinery, paving the way for sustained growth and innovation in this dynamic sector.

Proper installation of cable machinery is crucial to ensure optimal performance and longevity of the equipment. The installation process should be conducted with careful attention to detail, as improper setup can lead to inefficiencies and even costly damages. Ensuring all components are correctly aligned and secure will minimize wear and tear, ultimately extending the lifespan of the machinery. Additionally, technicians should be trained and familiar with the specific requirements of the installation to prevent potential pitfalls that can arise from a lack of understanding.

Furthermore, the significance of adhering to manufacturer guidelines during installation cannot be overstated. These guidelines are designed to ensure that the machinery operates within its optimal parameters and meets safety standards. A failure to follow these directives may not only hinder performance but can also compromise safety, putting both the equipment and operators at risk. By emphasizing the importance of proper installation techniques and regular maintenance, businesses can significantly enhance productivity and reduce the likelihood of unexpected breakdowns, thereby facilitating smooth operational workflows.

Preparing your workspace is a critical step for ensuring a safe and efficient installation of cable machinery. Start by clearing the area of any clutter or obstacles that could impede your workflow or pose safety hazards. This means removing unnecessary tools, equipment, or materials that are not directly related to the installation process. A well-organized workspace not only promotes efficiency but also minimizes the risk of accidents, allowing you to focus solely on the task at hand.

Next, ensure that your workspace is well-lit and adequately ventilated. Proper lighting is essential for precision work, as it helps you see intricate components and avoid mistakes. Additionally, good ventilation is crucial when working with machinery that may produce fumes or dust. Consider using fans or opening windows to create a comfortable environment. Lastly, make sure you have all necessary tools and safety equipment readily accessible. This includes gloves, goggles, and any specialized tools required for the installation. Preparing your workspace thoughtfully will set the stage for a smooth and successful cable machinery installation.

| Preparation Step | Description | Tools Required | Safety Measures |

|---|---|---|---|

| Workspace Cleanup | Remove any debris or obstacles from the installation area to ensure a clear working space. | Broom, Vacuum Cleaner | Wear appropriate safety footwear to prevent slips and falls. |

| Equipment Inspection | Check all machinery and tools for functionality and any damage prior to installation. | Inspection Tools, Checklist | Use gloves when handling tools and machinery. |

| Plan Layout | Design a layout for the machinery that optimizes space and accessibility. | Measuring Tape, Graph Paper | Ensure a clear path for emergency exits and access points. |

| Check Power Supply | Ensure the power supply meets the machinery specifications and is safe to use. | Voltage Meter, Extensions Cords | Disconnect power before installation to prevent accidents. |

| Assemble Tools | Gather all necessary tools for assembling and installing the machinery. | Toolbox with Wrenches, Screwdrivers, etc. | Always use the right tool for the job to prevent injury. |

Installing cable machinery components correctly is essential for ensuring optimal performance and longevity. This step-by-step guide aims to simplify the installation process, allowing operators to achieve maximum efficiency and safety. According to the International Cable & Wire Association, improper installation can lead to a 25% decrease in machine performance, highlighting the importance of following best practices.

Begin by preparing the site. Ensure that the installation area is clean, dry, and free of obstructions. Proper grounding is vital to prevent electrical malfunctions; a study by the Electrical Safety Foundation International noted that nearly 30% of electrical failures in machinery are due to inadequate grounding. Once the groundwork is set, proceed with aligning components accurately. Misalignment can result in increased wear and tear, leading to costly downtime and repairs—research shows that misaligned machinery can cause a 15-20% increase in operational expenses.

Next, adhere to the manufacturer's specifications for assembling the components. Use calibrated tools to avoid over-tightening or under-tightening connections, which can jeopardize system integrity. A comprehensive report from the Machinery Maintenance Institute indicated that regular maintenance and proper installation techniques can enhance machinery lifespan by up to 40%. Following these guidelines will not only promote performance but also ensure a safe working environment for all operators involved.

Testing installed cable machinery is crucial to achieve optimal performance and ensure long-term reliability. After the machinery has been installed, the first step in the testing process involves a thorough inspection of all components and connections. This includes checking the alignment of cables, examining the integrity of splices, and ensuring that all fasteners are secured properly. A visual inspection helps identify any potential issues that could compromise the machinery's efficiency.

Following the initial inspection, the next phase involves functionality testing. This can be performed by initiating the machinery in a controlled environment, monitoring its operation under various loads and conditions. It’s important to verify that the machinery operates within the recommended parameters—observing factors such as tension, speed, and operational noise. Any anomalies observed during this phase should be documented for further analysis. In addition, conducting routine performance assessments after installation allows for adjustments to be made before full-scale operation begins, mitigating the risk of unexpected breakdowns and enhancing overall productivity.

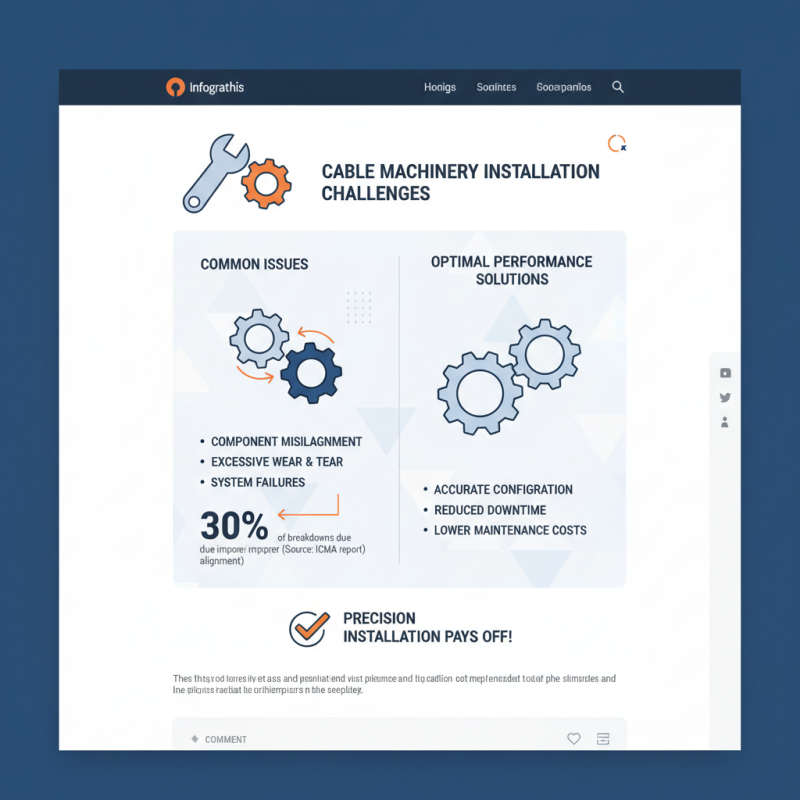

Installing cable machinery can be a complex process, often hampered by various common issues that can disrupt optimal performance. One of the primary challenges is the misalignment of components, which can lead to excessive wear and tear and even system failures. According to a report by the International Cable Machinery Association, nearly 30% of machinery breakdowns are attributed to improper alignment during installation. Ensuring that all components are configured accurately can significantly reduce downtime and maintenance costs.

Another frequent issue observed during cable machinery installation is improper cable handling, which can result in damage to the cables themselves. The same association notes that approximately 20% of cable failures stem from mishandling practices during installation. To address this, it’s essential to train personnel on best practices for cable management, including using proper tools and techniques to minimize stress and prevent kinks. Implementing a thorough inspection checklist prior to operation can also help identify potential installation flaws that could lead to costly repairs in the future.