In the ever-evolving world of telecommunications, the demand for efficient and reliable equipment is crucial. This includes machines that coat optical fibers. A Second-Hand Optical Fiber Coating Machine can offer substantial cost savings for businesses, especially startups. Purchasing used machines can be a smart choice, but it requires careful consideration.

When looking for a second-hand optical fiber coating machine, it’s vital to assess the condition and functionality of the equipment. Some machines may have hidden wear and tear. Others could be outdated, leading to inefficiencies. However, the right choice can enhance production quality and lower operational costs.

There’s always a risk associated with buying used equipment. Each machine has a history, and not all will meet current industry standards. Finding the best options requires due diligence. In this guide, we will explore the top five second-hand optical fiber coating machines for sale. Whether you are expanding your production line or starting fresh, these insights will help you make an informed decision.

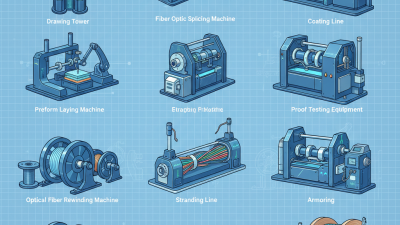

When exploring second-hand optical fiber coating machines, it's essential to understand their importance in the manufacturing process. These machines are crucial for protecting fiber optics from environmental damage. A well-coated fiber optic offers better performance and durability. However, choosing a second-hand machine requires careful evaluation.

Tip: Look for machines with minimal wear and tear. Inspect the coating rollers and application systems closely. Small damages can lead to significant production issues later.

Finding the right machine often involves checking the specifications. Ensure it meets your production needs. Not all machines are created equal, and some might lack the necessary features. Research is key to avoiding regretful purchases that might cost more in the long run.

Tip: Seek feedback from previous users. Their insights can reveal hidden flaws or benefits. Remember, not every used machine is a bargain. Sometimes, a cheaper option can end up being a poor investment.

When searching for second-hand optical fiber coating machines, quality is paramount. Start by assessing the machine's condition. Look for signs of wear and tear. Rust or broken parts can indicate poor maintenance. Even minor dents can affect performance. Inspect the machine closely to ensure it meets your needs.

Additionally, consider the machine's capabilities. Does it offer the features you require? Compare its specifications with your production goals. Flexibility in coating types can be a significant advantage. Think about how easily it can adjust to different requirements. If modifications are needed, check the availability of upgrade options.

Price is another crucial factor. While bargains are tempting, be wary. An exceptionally low price may signal hidden issues. Ensure you factor in potential repair costs. A machine might seem affordable at first. However, ongoing maintenance and parts could drive up expenses. Make informed decisions to avoid future regret.

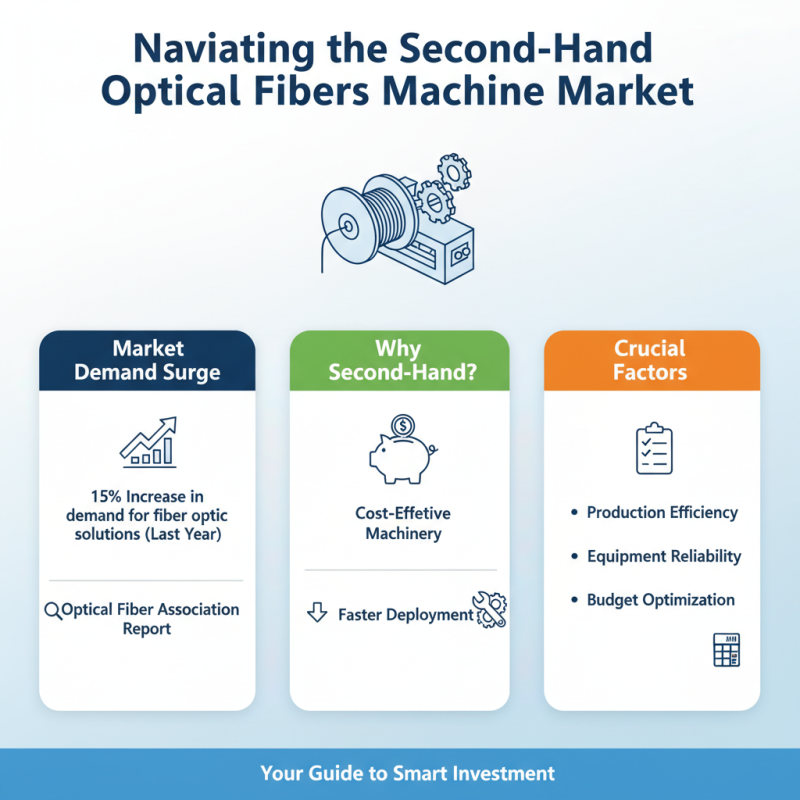

The search for reliable second-hand optical fiber coating machines is crucial in today’s fast-paced market. An industry report by the Optical Fiber Association noted that the demand for fiber optic solutions has surged by 15% in the last year. This growing demand pushes manufacturers to seek cost-effective machinery. Choosing the right second-hand equipment can drastically affect production efficiency and cost.

When considering a second-hand machine, it’s important to inspect its operational history. Age does not necessarily indicate poor quality. Numerous older models still outperform newer, untested systems. Look for machines that have been regularly maintained. This factor can significantly enhance the longevity of your investment.

**Tip:** Always request a demonstration before purchase. This will help you assess the machine's functionality and assess performance potential. Additionally, evaluate available support services. Some used equipment might lack sufficient documentation, raising questions about their operational reliability.

In an ever-evolving marketplace, staying updated with technological advancements is essential. The right choice can make a positive difference. Reflecting on specific experiences from past purchases can guide better decision-making. Analyzing previous mistakes leads to improved outcomes.

When searching for second-hand optical fiber coating machines, one must evaluate various features. Many machines offer unique specifications, such as coating speed, precision, and ease of use. Some devices may have advanced digital controls, while others rely on manual settings. The difference in user interfaces can significantly impact workflow efficiency.

Pricing is another crucial aspect. Second-hand machines come at different price points. A basic model may start at a lower price, but it could lack essential features. On the other hand, a more costly option might include superior technology or a reliable track record. Consideration of maintenance history can inform whether a machine is worth the investment.

It’s tempting to choose the cheapest option available. However, cheaper does not always mean better. Some sellers may not disclose previous issues, leading to regrets later. A careful analysis of features versus pricing is vital. Investing in a high-quality machine can save costs in the long run.

| Model | Max Input Fiber Diameter (mm) | Coating Type | Production Speed (m/min) | Price (USD) |

|---|---|---|---|---|

| Model A | 0.25 | Polymer | 50 | $15,000 |

| Model B | 0.2 | UV Cure | 70 | $18,000 |

| Model C | 0.3 | Silicone | 55 | $12,000 |

| Model D | 0.25 | Thermal | 60 | $20,000 |

| Model E | 0.28 | Epilog | 75 | $17,500 |

When purchasing second-hand optical fiber coating machines, consider their condition carefully. Look for signs of wear and tear, especially on critical components. A thorough inspection can reveal hidden issues. Pay attention to the machine’s age and any past repairs. These factors can significantly affect performance and lifespan.

Maintenance is equally important after your purchase. Regular cleaning is crucial; dust and debris can hinder operation. Proper lubrication keeps the machine running smoothly. Document all maintenance actions to track the machine's performance over time. If replacements are needed, source compatible parts to ensure seamless functionality.

Don't forget to listen to the machine while it operates; unusual noises can indicate problems.

Be mindful of the machine’s efficiency. Testing different parameters can help you find the optimal settings. Sometimes, a small adjustment makes a huge difference. Always be prepared for unexpected challenges. Machines may require troubleshooting, and patience is essential. Learning from these experiences can lead to better decisions in the future.