In the world of cable manufacturing, Cable Insulation Machines play a crucial role. These machines ensure the safety and efficiency of electrical products. Proper insulation prevents short circuits, electrical fires, and system failures.

The right machines can streamline production while maintaining quality. Different types of cable insulation machines exist, each serving specific functions. They vary in size, speed, and complexity. As technology advances, newer models emerge, blending innovation with practicality.

However, the selection process can be daunting. Manufacturers must consider their specific needs. Not all machines are created equal; some may underperform or lack the latest features. It’s essential to evaluate options critically. This article explores the top 10 cable insulation machines worth knowing. Each machine has its strengths and weaknesses, prompting a deeper look into their features and effectiveness.

Cable insulation machines play a crucial role in the wire and cable manufacturing industry. They apply insulating materials to conductors, ensuring safety and efficiency. Different types of machines serve various needs. Some focus on extrusion processes, while others utilize winding techniques. Each machine has its unique advantages.

When choosing a machine, consider its capacity. Not all projects require high output. Sometimes, smaller machines are more cost-effective for limited runs. Inspect the machine's maintenance requirements. Regular upkeep can prevent costly downtime.

Tips: Always evaluate the insulation material compatibility. A mismatch can lead to faulty cables. Additionally, think about the space where the machine will operate. An overcrowded area may limit efficiency. Also, review energy consumption; it affects overall production costs.

Investing in the right equipment is vital. However, it's easy to overlook details. Reflect on your specific needs before making a decision. This can save time and resources down the line. The right machine impacts not just production but safety as well.

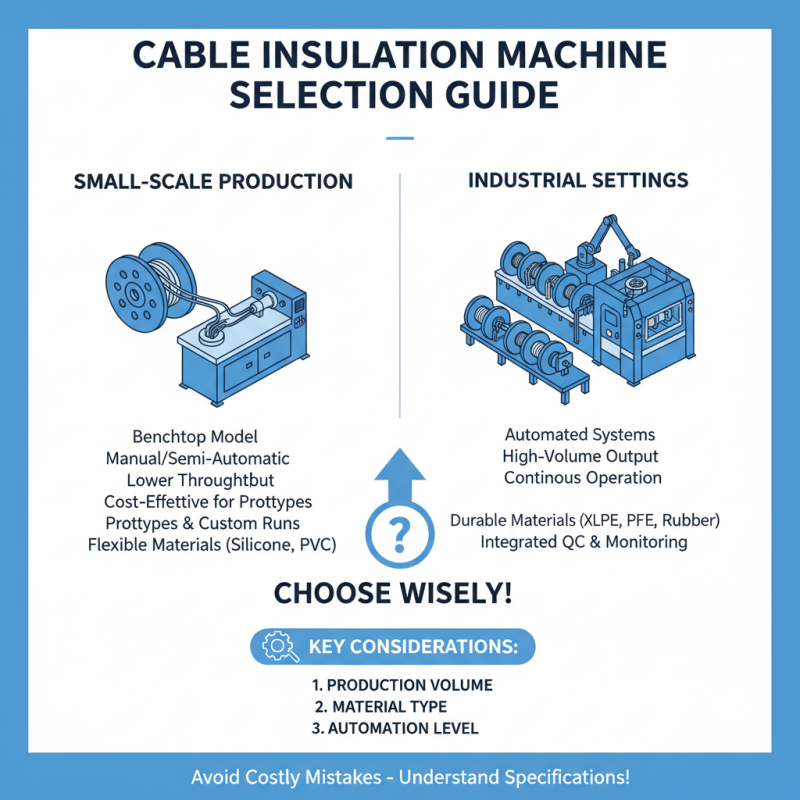

Choosing the right cable insulation machine can be a daunting task. Several factors come into play. The production capacity is crucial. A machine should meet your daily output needs. Consider the speed of operation as well. Faster machines improve productivity but can be harder to manage.

Durability is another key criterion. Look for machines built with robust materials. They should withstand continuous use without frequent breakdowns. Maintenance is vital too. Some machines require more upkeep, which can affect long-term costs.

User-friendliness is essential. Complex controls can slow down workers. Machines that are easy to set up can save time. Finally, do not overlook safety features. Ensure the machine has proper safeguards to protect operators. Balancing these factors can be challenging, but it leads to better choices.

| Model | Insulation Type | Maximum Cable Diameter (mm) | Production Speed (m/min) | Power Consumption (kW) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | PVC | 25 | 50 | 15 | 300 |

| Model B | PE | 30 | 60 | 20 | 350 |

| Model C | XLPE | 28 | 70 | 25 | 400 |

| Model D | EPR | 35 | 80 | 30 | 450 |

| Model E | TPE | 40 | 90 | 35 | 500 |

| Model F | PVC | 45 | 100 | 40 | 550 |

| Model G | PE | 50 | 110 | 45 | 600 |

| Model H | XLPE | 55 | 120 | 50 | 650 |

| Model I | EPR | 60 | 130 | 55 | 700 |

| Model J | TPE | 65 | 140 | 60 | 750 |

When it comes to cable insulation machines, choosing the right one is crucial. These machines vary significantly in design and functionality. Some are suited for small-scale production, while others work well in industrial settings. Understanding the specifications is essential to avoid costly mistakes.

Tips: Always check machine reviews. Look for feedback from users. This can provide valuable insights into performance and reliability. Many manufacturers offer demo units. Try them out before making a final decision.

The top machines often excel in their capabilities. Some can handle multiple wire sizes, enhancing their versatility. Others may have limitations, which can hinder your production flow. Choosing a machine without understanding your needs can lead to inefficiencies.

Tips: Keep maintenance in mind. Regular checks can extend machine life. Sometimes, a less expensive machine performs better if well-cared for. Knowing your long-term goals can guide you toward the right choice.

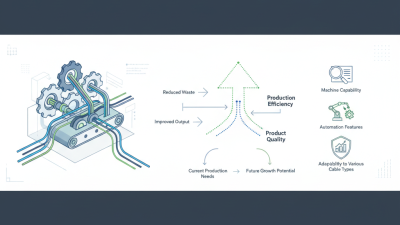

When choosing cable insulation machines, performance and features play a crucial role.

A recent industry report highlighted that machinery efficiency can directly impact production speed by up to 25%.

This means a machine that operates at optimal efficiency not only saves time but also reduces overall costs. Many machines feature

advanced heat management systems, which can ensure a consistent insulation process.

However, some machines struggle with temperature control.

This inconsistency can lead to defects in insulation quality.

The comparative analysis shows that machines with multi-layer insulation capabilities

can significantly enhance output. These devices can handle various materials, ensuring versatility. The speed of processing can vary.

Some machines can process up to 600 meters per minute. Yet, not all models maintain

consistent performance under heavy loads. Users reported that machines

occasionally fail to handle thicker cables effectively, which presents a challenge. Robust testing is essential for determining which machine

suits specific requirements.

Another critical aspect is maintenance.

Machines with complex components can lead to longer downtimes. A survey indicated that approximately 30%

of manufacturers face issues with machine reliability. Regular maintenance can mitigate these issues, but it requires time and expertise.

A machine that is user-friendly and easy to maintain can make a significant difference

in operational efficiency.

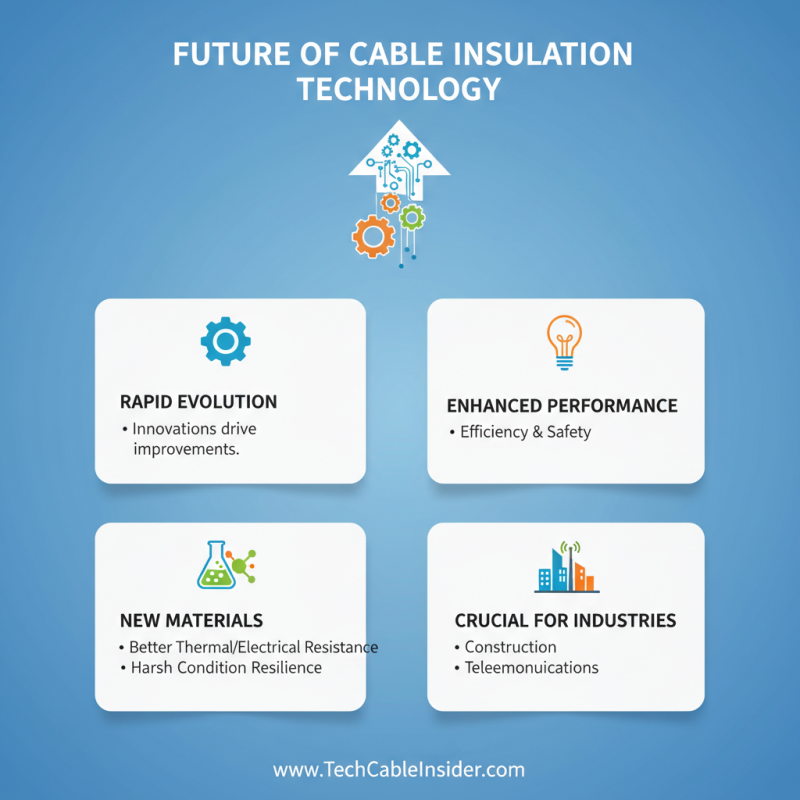

The future of cable insulation technology is evolving rapidly. Innovations are driving improvements in materials and processes. This shift aims to enhance efficiency and safety. New materials are being developed that offer better thermal and electrical resistance. These materials can withstand harsher environmental conditions. This is crucial for industries ranging from construction to telecommunications.

Another trend is automation in cable insulation machines. Automated systems streamline production. They reduce the chances of human error. Integrated sensors can monitor quality in real-time. However, reliance on automation raises concerns about job security in the workforce. Balancing technology and employment is a challenge.

Sustainability is also a growing focus. Manufacturers are exploring eco-friendly insulation options. Biodegradable materials are gaining traction. Yet, achieving the right balance between performance and sustainability is not easy. Companies need to rethink their strategies. The journey towards a greener future is complex but necessary.