As the demand for high-quality coatings grows, choosing the right Coating Machine becomes crucial. Industry expert Dr. Emily Johnson emphasizes, “Investing in advanced Coating Machines can significantly boost productivity and quality.” Understanding the features and technology behind these machines is essential for businesses aiming to improve their processes.

In 2026, several top Coating Machines promise innovative capabilities. These machines incorporate cutting-edge technology to enhance efficiency and reduce waste. However, not every machine suits every application. It's vital to assess your specific needs before making a purchase. An ill-informed choice can lead to costly setbacks and inefficiencies.

Many companies overlook important factors during their decision-making. This oversight can result in underperforming equipment that fails to meet production standards. Take the time to research and analyze various options. Understanding specifications and performance ratings can help avoid potential pitfalls. Investing in the right Coating Machine will pave the way for future success.

When considering top coating machines in 2026, certain features stand out. Look for versatility as a key quality. A machine that can handle various materials like metals, plastics, and ceramics is invaluable. Different industries have different needs. The ideal machine adapts to these needs seamlessly.

Mobility can also be a game-changer. A portable design allows for use in multiple locations.

Moreover, automation is essential in 2026's coating machines. Machines with smart technology can streamline production processes. They reduce the need for manual input, thus minimizing human error. However, reliance on automation can raise concerns. It’s important to evaluate the balance between technological dependence and skilled labor.

Energy efficiency is another critical aspect. Machines that consume less energy help cut costs. Still, one must consider their initial investment. Higher efficiency often comes with a price tag. Reflect on the long-term savings versus the upfront costs. Each feature, from energy consumption to mobility, requires careful thought.

Coating technology plays a crucial role across various industries. There are different types of coating machines available. Each of these technologies caters to specific needs. Understanding these types is vital before making a purchase.

Spray coating is one of the most popular methods. It allows for uniform application and excellent coverage. According to a 2023 industry report, spray technologies account for nearly 30% of the market share. This method is widely used in automotive and aerospace industries. However, it can lead to overspray and material waste. This aspect should be carefully evaluated.

On the other hand, powder coating has gained traction in recent years. It uses dry powder instead of liquid paint. This technique is more environmentally friendly. The global powder coating market is expected to reach $20 billion by 2026. While this technology offers durability, it requires careful surface preparation. Neglecting this can lead to poor adhesion. Thus, ensuring proper setup is essential. Each coating technology has its pros and cons. Making an informed decision is key to optimizing coating processes.

| Coating Technology | Application | Advantages | Considerations |

|---|---|---|---|

| Electrostatic Coating | Automotive, Appliances | High transfer efficiency, uniform coating | Initial setup cost, limited to electrically conductive substrates |

| Powder Coating | Metal furniture, Industrial parts | Durability, environmentally friendly | Requires curing oven, surface preparation |

| Liquid Coating | Wood, Plastics | Versatile, wide range of finishes | Less efficient than powder, VOC emissions |

| UV Coating | Packaging, Paper products | Fast curing, high gloss finishes | Depends on UV light, higher equipment cost |

| Thermal Spray Coating | Aerospace, Marine | Excellent wear resistance, customizable | Complex process control, skill-dependent |

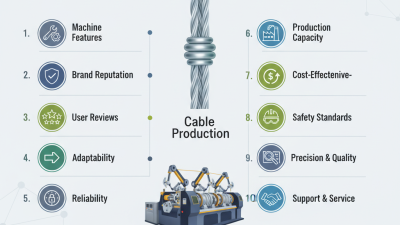

When considering the purchase of coating machines, several factors come into play. Industry reports suggest that 70% of buyers prioritize efficiency and output capacity. Modern coating machines must adapt to various materials and production speeds. This flexibility can significantly enhance your operational workflow.

Cost is another crucial aspect. A recent analysis indicated that up to 40% of businesses face budget constraints. It's essential to weigh the long-term benefits of advanced technology against initial investments. Choosing a machine that fits within your budget yet offers high performance is not easy.

Maintenance requirements should not be overlooked. Some machines may promise high productivity but require frequent upkeep. This could lead to unexpected costs and downtime. Understanding your team's capabilities for maintenance can influence your choice significantly.

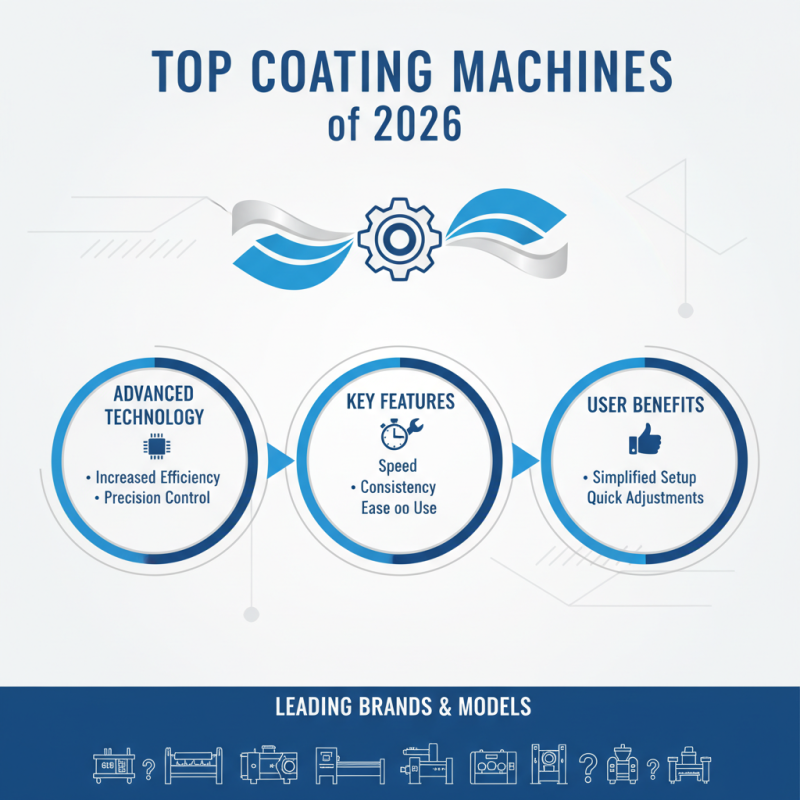

When exploring the top coating machines of 2026, several key brands and models stand out. These machines offer advanced technology, enhancing efficiency in various coating applications. Their precision gives users more control. It's crucial to evaluate features like speed, consistency, and ease of use. Many users appreciate machines that simplify setup and adjustments.

While some models boast impressive capabilities, they may come with a learning curve. Users often find themselves overwhelmed by complex interfaces. Training may be necessary to unlock the machine’s full potential. It’s not uncommon for users to have initial challenges in achieving desired outcomes. Reviews can be helpful, but practical experience often tells a different story.

Consider the machine's size and required maintenance. Some compact models are easier to handle but may lack power. Larger machines often provide more robust performance but occupy significant space. Balancing these aspects can be tricky. Ensure that your choice aligns with your operational needs for optimal results.

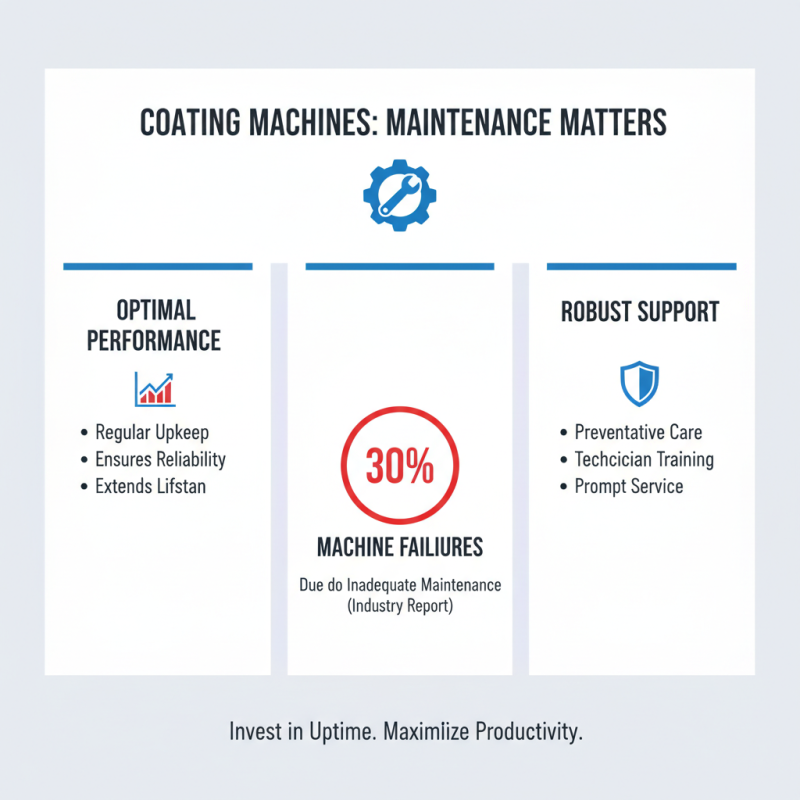

When considering coating machines, maintenance and support are vital factors. Regular upkeep ensures optimal performance. According to industry reports, 30% of machine failures stem from inadequate maintenance practices. This statistic highlights the necessity of a robust maintenance program.

Support services can greatly influence operational efficiency. Companies often offer varying levels of support, ranging from basic troubleshooting to full-on maintenance packages. It's crucial to understand what you will receive after a purchase. A well-structured support plan can drastically reduce downtime. Research shows that companies with comprehensive support protocols experience 25% less machine downtime.

Moreover, the learning curve can be steep. Operators need training to handle advanced coating machines. Ineffective training can lead to improper usage, resulting in product defects. This emphasizes the importance of ongoing education. Operators must adapt to evolving technology and techniques. Quality support often includes training modules tailored for specific machines. This flexibility can enhance overall performance and lead to better product quality.