In the rapidly evolving telecommunications industry, the demand for high-quality optical fiber cables has skyrocketed, necessitating the use of advanced manufacturing equipment. Optical Fiber Cable Machinery plays a crucial role in streamlining production processes, ensuring that manufacturers can meet the growing market needs with speed and efficiency. As technology continues to advance in 2023, the machinery used for producing optical fiber cables has become more sophisticated, incorporating automation and precision engineering to enhance output and reduce operational costs.

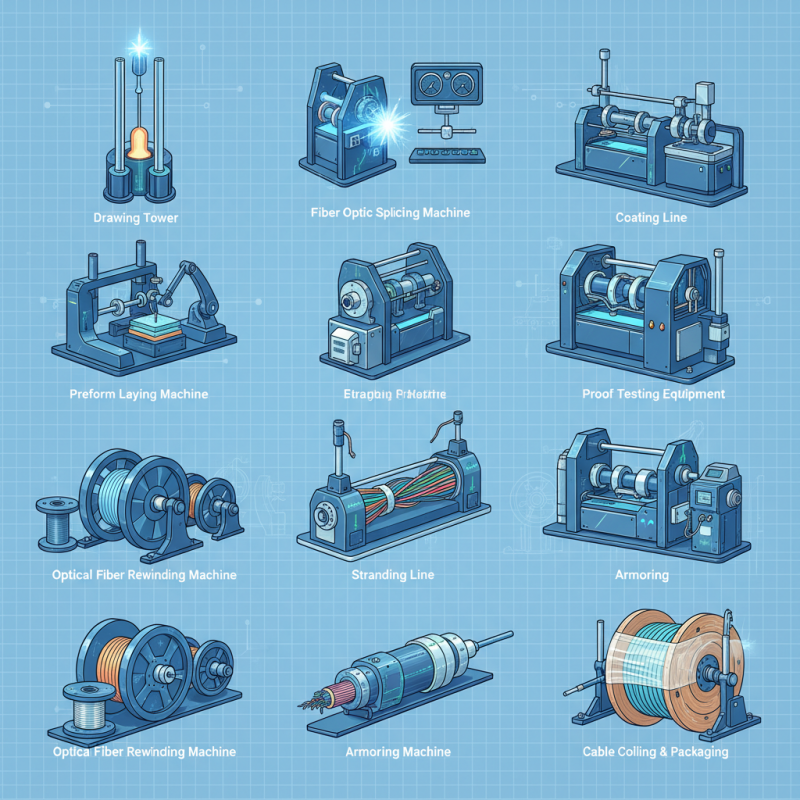

This article explores the top 10 optical fiber cable machinery that are redefining production efficiency in the industry. From drawing towers to coating lines, these machines are designed to optimize various stages of cable manufacturing, facilitating better quality control and minimizing waste. Understanding the capabilities and innovations of these machinery solutions is essential for manufacturers looking to stay competitive in an increasingly demanding landscape. As we delve into the key features and benefits of these top machines, we will highlight how they contribute to the effectiveness of optical fiber cable production and support the technological advancements that define modern communication systems.

In 2023, the landscape of optical fiber cable machinery has seen significant advancements driven by the growing demand for high-speed internet and data transmission. Manufacturers are increasingly integrating automation and smart technologies into their machinery, enhancing both production efficiency and precision. The implementation of Industry 4.0 practices, including the use of IoT-enabled devices, allows for real-time monitoring and data analytics, leading to optimized operations and reduced downtime. This shift towards automation also addresses labor shortages and elevates the skills required in the workforce.

Another notable trend is the emphasis on sustainability within the optical fiber manufacturing process. Environmental considerations have prompted companies to focus on reducing waste and energy consumption. New machinery designs are incorporating eco-friendly materials and processes that not only lower the carbon footprint but also improve overall productivity. This commitment to sustainability is becoming an essential aspect of competitive differentiation in the market, with manufacturers seeking to meet the increasing regulatory requirements and consumer expectations for greener practices. Overall, the optical fiber cable machinery sector in 2023 is characterized by innovation, efficiency, and a forward-thinking approach to environmental stewardship.

In the realm of optical fiber production, efficiency is paramount. The modern machinery designed for this purpose incorporates several key features that significantly enhance productivity. One of the most crucial characteristics is automation, which reduces manual intervention and minimizes human error. By integrating advanced robotics and automated processes, manufacturers can achieve a streamlined workflow that not only speeds up production times but also ensures consistent quality in the end product.

Another essential feature is the ability to adapt to various cable specifications. High-efficiency optical fiber production equipment is equipped with versatile settings that allow for quick adjustments to accommodate different fiber types, sizes, and coatings. This adaptability is vital for meeting the diverse demands of the telecommunications market, enabling manufacturers to cater to specific client needs without sacrificing efficiency. Additionally, advanced monitoring systems provide real-time feedback on production parameters, ensuring that any deviations can be promptly addressed, further optimizing the production process and reducing waste.

The optical fiber machinery market has seen significant growth in recent years, driven by the increasing demand for high-speed internet and telecommunications. Leading manufacturers in this space have carved out substantial market shares, thanks to their innovative technologies and efficient production processes. Understanding the competitive landscape is crucial for businesses looking to invest in or upgrade their optical fiber cable production capabilities. Market leaders typically focus on automation, energy efficiency, and precision engineering, which not only enhance production speeds but also improve product quality.

Tips for assessing manufacturers include researching their technological advancements and customer reviews, as well as looking into their production capacities and after-sales services. Collaborating with a manufacturer that not only sells machinery but also provides ongoing support can greatly enhance production efficiency. Moreover, consider exploring partnerships with companies that have a proven track record in the optical fiber industry, as this can lead to shared knowledge and faster problem-solving down the line.

As the industry evolves, keeping an eye on emerging players is equally important. Technological innovation is happening at a rapid pace, and newer entrants may bring unique solutions that challenge established brands. By staying informed and flexible, businesses can better position themselves to adapt to market changes and seize new opportunities in optical fiber cable production.

| Rank | Manufacturer | Market Share (%) | Key Machinery Types | Estimated Annual Production Capacity (km) |

|---|---|---|---|---|

| 1 | Manufacturer A | 25% | Fiber Drawing Towers, Coating Machines | 100,000 |

| 2 | Manufacturer B | 18% | Concentric Neutral Layer Equipment, Testing Tools | 80,000 |

| 3 | Manufacturer C | 15% | Fiber Optic Splicing Machines, Fusion Splicers | 70,000 |

| 4 | Manufacturer D | 12% | Pulling and Laying Machines, Cable Reels | 50,000 |

| 5 | Manufacturer E | 10% | Laser Fusion Splicing, Cable Testing Equipment | 40,000 |

| 6 | Manufacturer F | 8% | Optical Fiber Cable Extruders, Cabling Equipment | 35,000 |

| 7 | Manufacturer G | 6% | Cable Sheathing Units, Multi-fiber Units | 30,000 |

| 8 | Manufacturer H | 5% | Optical Fiber Testing and Inspection Equipment | 25,000 |

| 9 | Manufacturer I | 4% | Inline Testing Equipment, Quality Control Machines | 20,000 |

| 10 | Manufacturer J | 2% | Cable Packaging and Handling Systems | 10,000 |

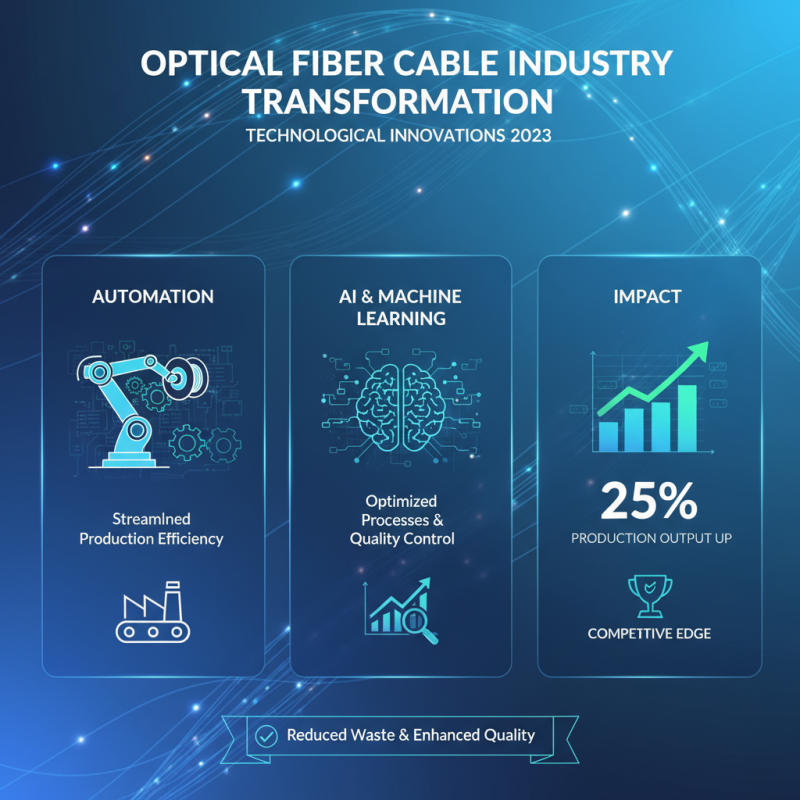

The optical fiber cable industry has been experiencing significant transformations due to technological innovations that streamline production efficiency. In 2023, advancements in automation, especially the incorporation of AI and machine learning algorithms, have enabled manufacturers to optimize production processes, reduce waste, and enhance quality control. Reports suggest that the adoption of these technologies can improve production output by up to 25%, ensuring manufacturers maintain a competitive edge in an increasingly demanding market.

Another critical innovation is the development of advanced materials and designs, which facilitate faster and more flexible fiber deployment. According to recent industry findings, the integration of thin and lightweight materials not only reduces material costs by approximately 15% but also enhances the installation speed of optical fiber networks. This shift is crucial as telecommunications and data transmission demands continue to surge globally.

Tips: To further boost operational efficiency, manufacturers should invest in staff training on the latest technologies and methodologies in fiber production. Moreover, regular maintenance of machinery can prevent costly downtimes and ensure smooth operations. Emphasizing continuous monitoring and data analytics will also provide insights into production patterns and areas for improvement, allowing companies to adapt swiftly to market changes.

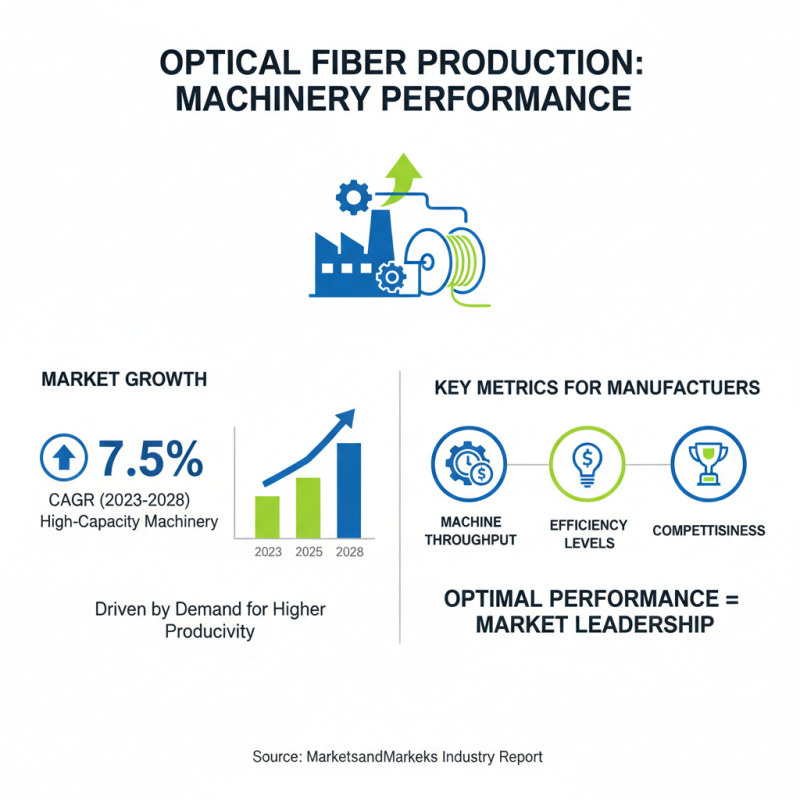

In the rapidly evolving landscape of optical fiber production, machinery performance metrics are becoming increasingly pivotal. According to a recent industry report by MarketsandMarkets, the demand for high-capacity optical fiber cable machinery is expected to grow at a CAGR of 7.5% over the next five years. This surge is primarily driven by the need for higher productivity benchmarks that many manufacturers are now striving to achieve. Leading manufacturers are identifying optimal machine throughput and efficiency levels as critical components for remaining competitive in this burgeoning market.

Key performance indicators (KPIs) for optical fiber machinery include throughput rate, energy consumption, and downtime. Research indicates that state-of-the-art fiber production equipment can achieve a throughput rate of up to 1,200 kilometers per day, significantly enhancing operational efficiency. Additionally, innovative machinery is designed to minimize energy usage, leading to a reduction of operational costs by approximately 15%. Maintenance practices also play a vital role in improving uptime. Advanced predictive maintenance strategies can reduce unplanned downtime by 30%, thus allowing manufacturers to meet the increasing demand without compromising on the quality of the optical fibers produced. These performance metrics not only help manufacturers align with industry standards but also contribute to a more sustainable production process.