In the ever-evolving landscape of fiber optic technology, businesses are continually seeking ways to optimize production costs while maintaining quality standards. One viable solution gaining popularity is the acquisition of second-hand optical fiber coating machines. These machines, designed for coating fibers to enhance durability and transmission efficiency, can provide significant savings compared to their brand-new counterparts. As the demand for high-quality optical fibers grows, the market for second-hand machinery has expanded, offering a diverse range of options tailored to various operational needs.

In this article, we will explore the top 10 second-hand optical fiber coating machines that stand out for their cost-effective solutions. From performance reliability to maintenance ease, we will delve into essential features that make these machines an attractive choice for businesses looking to enhance their fiber optic production capabilities without overwhelming their budgets. By investing in second-hand equipment, companies can benefit from advanced technology at a fraction of the cost, making it a strategic move in a competitive market. Join us as we uncover the best second-hand optical fiber coating machines that provide excellent value and performance for your fiber optic operations.

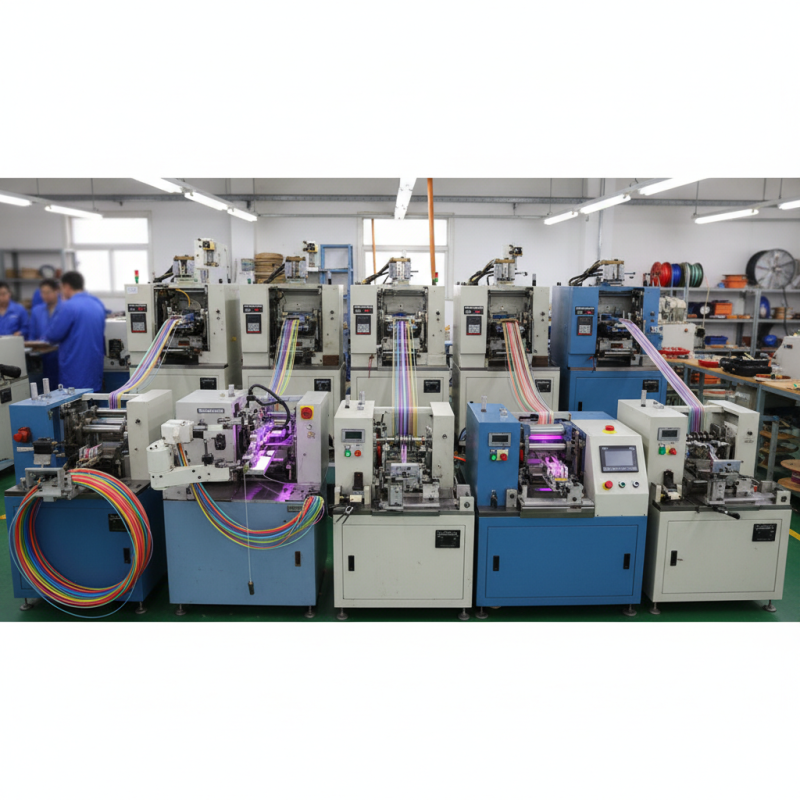

The market for optical fiber coating machines has seen significant growth in recent years, driven by the increasing demand for high-speed internet and improved telecommunications infrastructure. According to a report by the International Data Corporation (IDC), global data traffic is projected to increase by over 60% from 2022 to 2025. This surge necessitates efficient production capabilities, making second-hand optical fiber coating machines a cost-effective solution for many manufacturers looking to expand their operations without incurring exorbitant costs.

Second-hand optical fiber coating machines provide an attractive alternative to new machinery, typically costing 30-50% less while still delivering a high level of performance. Industry analysis indicates that these machines can achieve similar production rates and quality standards when properly maintained and refurbished. Moreover, organizations such as the Fiberoptic Association emphasize the importance of boosting production efficiency in fiber optic manufacturing, making such used equipment a viable choice for companies aiming to stay competitive in a rapidly evolving market.

In addition, the growing trend toward sustainability in manufacturing fosters an environment where purchasing second-hand machinery aligns not only with cost-saving strategies but also with corporate social responsibility goals. By opting for refurbished optical fiber coating machines, companies can reduce their carbon footprint and contribute to a circular economy. As the industry continues to adapt to changing technological advancements, second-hand equipment offers a strategic and economically savvy approach for manufacturers looking to enhance their production capabilities.

When selecting a cost-effective second-hand optical fiber coating machine, several crucial criteria must be taken into account to ensure a wise investment. First and foremost, the machine’s operational condition plays a pivotal role. A thorough inspection for signs of wear and tear, such as damaged components or excessive wear on mechanical parts, is essential. This evaluation helps to ascertain whether the machine has been maintained properly and can continue to perform reliably.

Another important criterion is the availability of replacement parts and technical support. Opting for machines from manufacturers that have a well-established presence in the market typically guarantees easier access to spare parts and technical assistance. Moreover, considering the machine’s compatibility with existing production processes can greatly enhance efficiency. Potential buyers should evaluate whether the coating machine can seamlessly integrate into their operations without necessitating significant modifications, as this can lead to cost savings in the long run.

Lastly, assessing the machine's performance history and output quality is vital. Requesting samples of previously coated fibers or testimonials from past users can provide insights into the machine's performance and consistency. By focusing on these criteria, buyers can ensure they are making a sound decision that aligns with their operational needs while keeping costs manageable.

This bar chart displays the costs of the top 10 second-hand optical fiber coating machines, providing a visual comparison to help in selecting cost-effective options.

The demand for optical fiber coating machines remains robust, given the continued expansion of optical communication and related industries. A recent report by Global Market Insights highlights that the optical fiber market is expected to cross $8 billion by 2026, driven by the need for high-speed internet and a growing emphasis on telecommunications infrastructure. Within this context, second-hand optical fiber coating machines present a cost-effective solution for companies looking to enhance their production capabilities without the burden of high capital expenditure.

When considering second-hand optical fiber coating machines, factors such as reliability, performance, and maintenance history play a crucial role in ensuring operational efficiency. Industry data indicates that properly maintained second-hand machines can operate effectively for several years, with minimal investment needed for upgrades or spare parts. Furthermore, sourcing used equipment allows companies to access advanced technology previously priced out of reach while significantly reducing the waste associated with manufacturing new machines. With a well-researched selection process, businesses can capitalize on the benefits offered by used optical fiber coating machines, ultimately contributing to both their bottom line and sustainable practices in equipment procurement.

In the optical fiber industry, opting for second-hand coating machines can offer significant cost savings without compromising quality. A recent report highlighted that businesses can reduce equipment expenditure by up to 50% when choosing used machinery. This can be particularly advantageous for small to mid-sized companies looking to expand their capabilities without incurring prohibitive costs. Purchasing second-hand equipment often allows companies to allocate resources towards other critical areas, such as research and development or marketing, which in turn can facilitate overall growth and innovation.

Additionally, the environmental benefits of utilizing second-hand equipment are noteworthy. The optical fiber industry, like many others, is often scrutinized for its environmental impact. By choosing refurbished machines, companies contribute to sustainability efforts by reducing waste and minimizing the demand for new raw materials. The International Telecommunications Union (ITU) reported that maximizing the lifecycle of existing equipment can significantly lower carbon footprints, supporting the industry's shift towards greener operations.

Tips: When considering the purchase of second-hand optical fiber coating machines, ensure to conduct a thorough evaluation of the equipment’s condition and history. It’s also beneficial to consult industry experts who can provide insights into the machine’s performance and reliability, helping you make an informed decision. Regular maintenance and operating within specified guidelines can extend the lifespan of these valuable assets.

| Model | Year | Condition | Price ($) | Production Capacity (km/h) | Warranty (Months) |

|---|---|---|---|---|---|

| Model A-1 | 2018 | Good | 15000 | 10 | 6 |

| Model B-2 | 2017 | Very Good | 12000 | 12 | 12 |

| Model C-3 | 2019 | Excellent | 18000 | 15 | 24 |

| Model D-4 | 2016 | Fair | 9000 | 8 | 3 |

| Model E-5 | 2020 | Like New | 20000 | 20 | 30 |

| Model F-6 | 2015 | Good | 8000 | 7 | 6 |

| Model G-7 | 2021 | Excellent | 22000 | 25 | 36 |

| Model H-8 | 2019 | Fair | 9500 | 9 | 2 |

| Model I-9 | 2020 | Like New | 21000 | 22 | 42 |

| Model J-10 | 2018 | Good | 12500 | 11 | 8 |

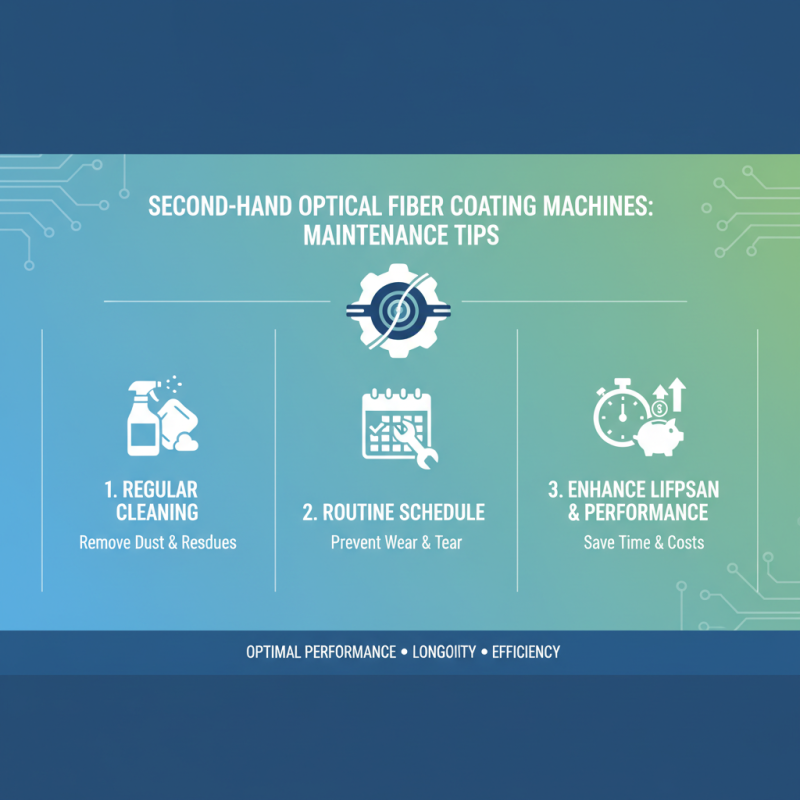

When investing in second-hand optical fiber coating machines, proper maintenance is crucial to enhance their lifespan and ensure optimal performance. Regular cleaning of the machine's components is essential; dust and residues can accumulate, negatively impacting the quality of the coatings applied. Implementing a routine maintenance schedule that includes checks for wear and tear can help identify potential issues before they escalate into significant problems, saving time and costs in the long run.

Additionally, monitoring the machine's calibration is vital for maintaining precision in production. Regularly assessing alignment and functionality will ensure that the coating process remains consistent and meets the desired standards. It's also important to keep an eye on the cables and other connecting parts for any signs of damage. Using the machine within its specified operating conditions and avoiding overload can significantly extend its operational life and efficiency.